What Is An Oil Water Separator, Its Types, And Advantages

The manufacturing process in various industries utilizes large amounts of water which subsequently generate wastewater. Often the wastewater stream contains oil, a result of direct use in the process or as lubricants. The oil in wastewater is required to be removed before discharge and reuse. Also, to protect the environment stringent discharge norms are set by government bodies which industries have to abide by.

So, What Is The Role Of An Oil Water Separator?

Oil water separator (OWS) system plays an important role in treating wastewater in almost all industries. A well-designed oil water separator system is an effective green solution to remove oil from the wastewater. It helps industries protect the environment, mitigate the risk of plant shut down due to non-compliance, and at the same time improve overall plant efficiency. Hence, understanding the working principle of OWS and identifying the right type of OWS is crucial.

Now, let’s dive in!

What is an Oil Water Separator?

To simply put, an oil water separator is an equipment used to separate oil and water mixtures into their separate components. Oil water separators can be designed to treat a variety of contaminants in water including free-floating oil, emulsified oil, dissolved oil, and suspended solids. There are different types of OWS, based on the type of contaminants a specific type of oil water separator system is deployed to remove oil from wastewater.

Types of OWS

The two types of OWS are gravity-based separators and coalescer separators.

1. Gravity-based separator:

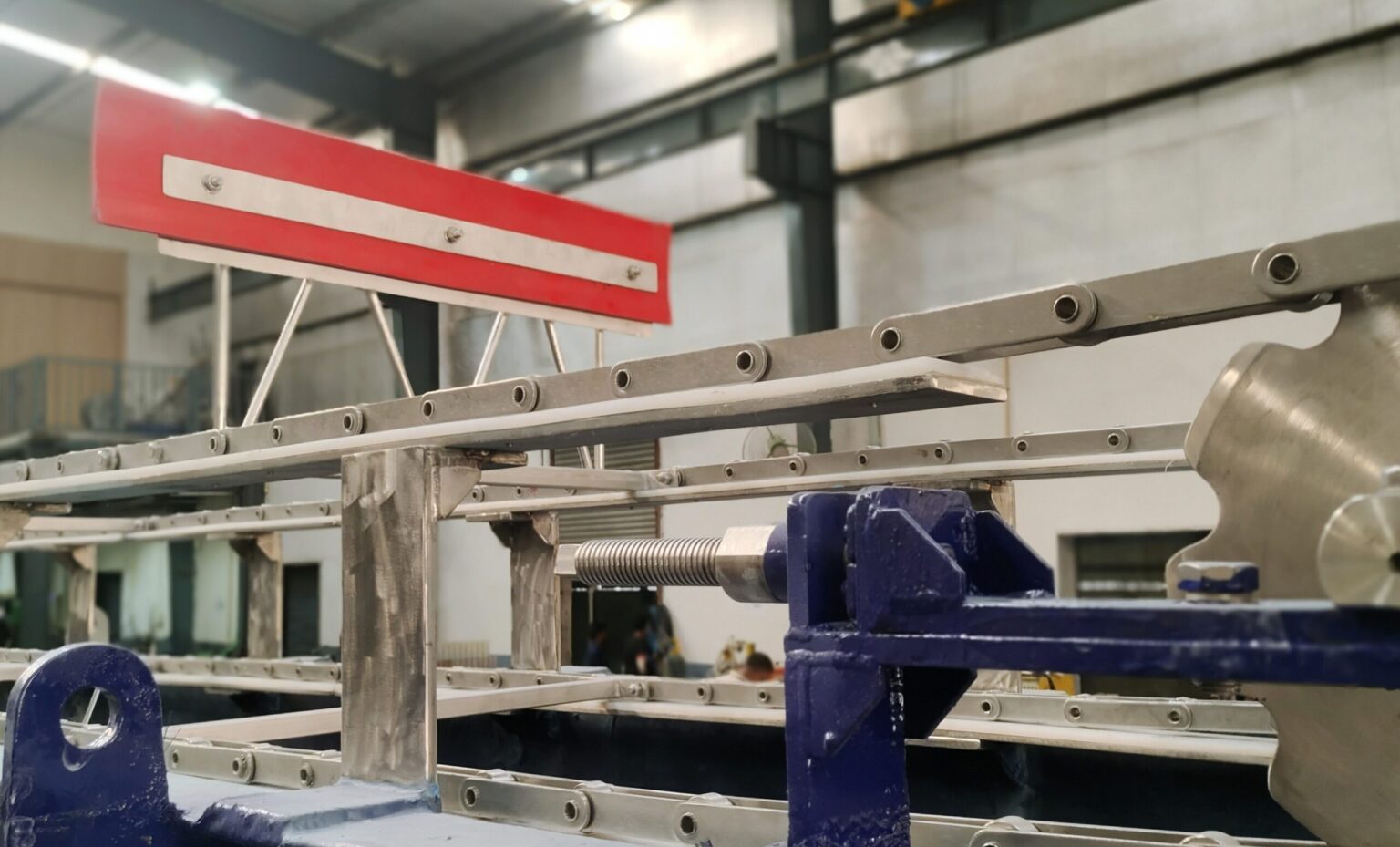

As the name suggests, this industrial oil water separator relies on the gravity difference between water and the specific gravities of oils. The different types of gravity-based separators are API Separator,Corrugated Plate Interceptor, Tilted Plate Interceptor, and Hydrocyclone Separator.

2. Coalescer separator:

In a coalescing separator, the flow of oil and water through the separator is similar to a gravity separator. However, an oleophilic media in incorporated in a coalescing separator. The oleophilic media enables the oil droplets to bind together on the surface of the media. By coalescing or binding together, the oil droplets increase in size and become more buoyant, thus rising to the surface swiftly, further enhancing separation.

Advantages of OWS

Primarily OWS is used to remove oil from water/wastewater. Based on the wastewater inlet parameters and site conditions & requirements a well-designed OWS can reap many benefits, which are:

-

- • Improved Process Efficiency: Effective oil removal from wastewater enhances process efficiency. For example, when an OWS is installed in a wastewater reuse treatment plant the chemical treatment, and filtration process is more effective due to the absence of oils. Also, the filtration performance is facilitated.

-

- • Reduced Maintenance: A well-designed oil water separator takes into account the challenges of the application and efficiently separates oil from water thereby enabling the efficient performance of downstream equipment ensuring low maintenance requirements.

-

- • Green Solution: OWS does not use any chemicals to separate oil and water. Thus, it is an

environment-friendly method of oil removal.

- • Green Solution: OWS does not use any chemicals to separate oil and water. Thus, it is an

-

- • Improved Savings: The reclaimed oil can be reused in the processes thereby reducing expenditure. No chemicals or consumables are required to separate oil and water thus substantially saving on recurring costs.

To summarise, an OWS is an integral part of industrial processes, a cost-effective green solution to separate oil and water. ASTM D7575 method can be used to test oil-grease in wastewater to design an efficient OWS. Based on-site conditions and discharge parameters customization of OWS may be required. Also, in some cases, a mobile oil water separator can be deployed.

An expert will help you gain maximum OWS benefits by designing an efficient-OWS, taking into account various parameters, while you meet the stringent norms that ensure environmental compliance.

Frequently Asked Questions(FAQs)

Q1. What are the benefits of using an oil skimmer?

A. One of the primary benefits of using an Belt Oil Skimmer is its ability to effectively remove oil from various sources. Whether it’s in industrial wastewater, coolant tanks, or process fluids, these devices can efficiently separate and collect floating oils. By doing so, they help prevent the contamination of water bodies and reduce the environmental impact caused by oil spills.

Q2. Where are sluice gates commonly used?

A. Sluice Gates are commonly used in various industries and applications where the control and management of water flow is crucial. These gates are typically found in hydraulic engineering projects, water treatment plants, irrigation systems, flood control systems, and even in some residential areas.

Q3. How does a mechanical bar screen work to remove debris from wastewater?

A. A Mechanical Bar Screens works by using a series of parallel bars or rods to capture and remove large debris from wastewater. The wastewater flows through the gaps between the bars, while the larger debris gets trapped on the upstream side. A cleaning mechanism, such as a rake or brush system, removes the captured debris for proper disposal.