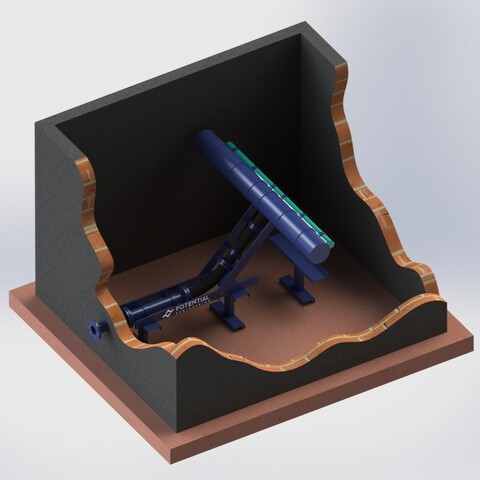

Effluent Decanter Overview

The scum/solids excluding type floating decanter use float to move up & down in the basin, and employs spring-loaded non-return valves to isolate the effluent piping from the surrounding mixed liquid. The design eliminates motors, gears, drive units, and other electromechanical components. The top and bottom movement of the decanter is restricted by the use of a stopper. It can be operated manually or PLC-based.

Effluent Decanter Specifications

Decanter Size

150 mm, 200 mm & 250 mm

Decanter Capacity at 3 m height (m3/h)

250, 425 & 680

Decanter Capacity at 1 m height (m3/h)

150, 215 & 350

Control

PLC based with manual overrides