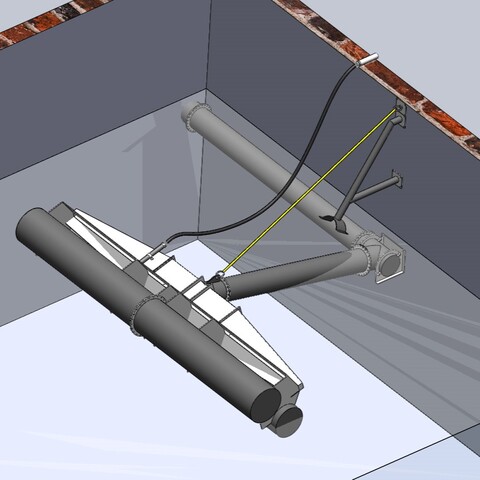

Ballast Decanter Overview

We manufacture Ballast decanter which is a scum/solid excluding floating type decanter for use in SBR/ Cyclic wastewater processes. The decanter is air powered and is driven by the plant’s aeration system. The decanter has two positions, cut-off and work. The decanter is moved in a vertical direction by injecting or releasing pressurized air into the body of the decanter.

Ballast Decanter Specifications

Decanter Size

300 mm, 400 mm, 500 mm & 600 mm

Decanter Capacity at 3 m height (m3/h)

850, 1575, 2450 & 2625

Three-way valve size

40 mm (for 300 & 400 mm decanter size) and 50 mm (for 500 & 600 mm decanter size)

Compressed Air

800 LPM (for 300 mm & 400 decanter size) and 2500 LPM (for 500 mm & 600 mm decanter size)

Compressed Air Pressure

0.05 Kg/cm2 for all decanter sizes