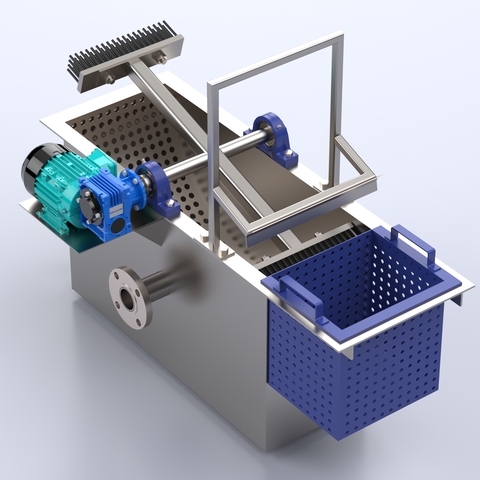

Rotary Brush Screen Overview

The Rotary Brush Screen is designed to remove fibers, hair, and other foreign objects from a waste stream. A semicircle perforated bed arrests debris from the wastewater. A rotating brush lifts the debris, which gets scrapped in an external drum or an in-built removable collection tank. This rotary screen is sitting on a filtrate tank. The brush is adjustable to accommodate wear & tear.

Rotary Brush Screen Specifications

Screen width :

up to 1500 mm. Wider on request

Minimum Perforation size :

1 mm

No of Brush :

2 or 4

Operation :

Motorized

MOC of Screen :

SS or Other material, on request

MOC of Brush :

PP/ Nylon/ other material on request