Multi-rake Bar Screen for High Capacity, Clog-Free Mechanized Screening

A wastewater treatment plant preliminary treats large solids, floating debris, and grit that can interfere with treatment processes or cause undue mechanical wear. Screens efficiently eliminate objects such as rags, paper, plastics, and metals to prevent damage and clogging of downstream equipment, piping, and appurtenances. A Multi rake Bar Screen is superior to the other screen types in preventing clogging and damage.

What is a Multi-rake Bar Screen?

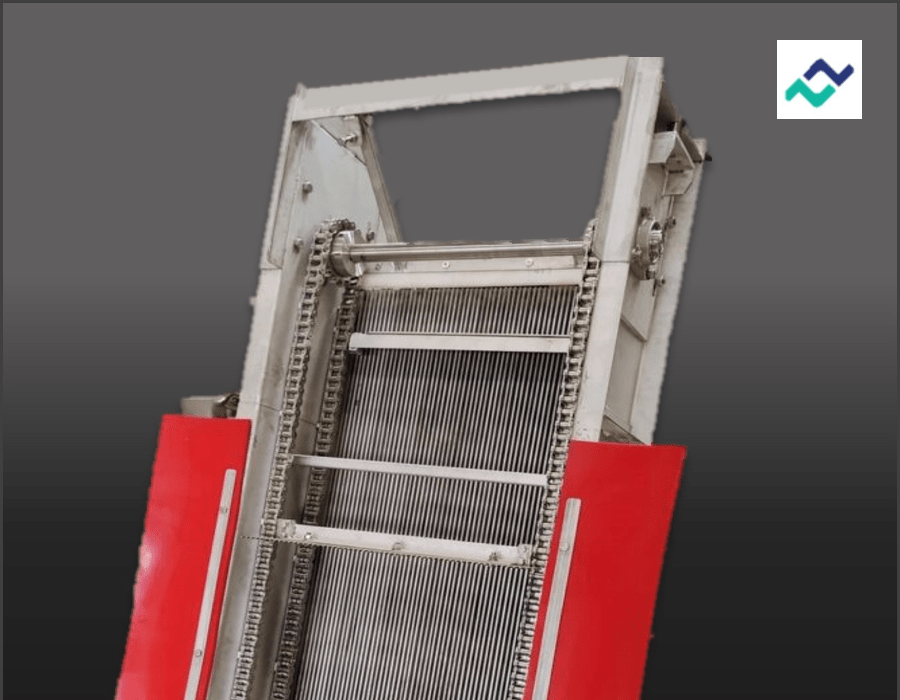

A Multi- rake Bar Screen is a mechanical screen. The screen comprises equally spaced inclined stationary bars, multiple mechanized rakes, and a wiper. The Multi-rake Bar Screen is vertically installed and remains partially submerged in the channel. Multi rake Bar Screen efficiently restricts floating debris from entering the subsequent treatment process.

Working of a Multi Rake Bar Screen

Multi rake Bar Screens are installed at inflow in wastewater treatment plants. This screen is partially submerged in the channel flow. The approaching wastewater flows through the inclined bar screens restricting the floating debris from entering the subsequent process. Depending on the space between the inclined bars, large, medium & fine debris can be restricted as per the requirements.

The debris on the inclined bars is cleaned with the help of mechanized rakes. These rakes are fixed between two chains which enables upward movement of the rakes. The teeth of these rakes engage between the inclined bars to carry the debris while moving upwards to the waste discharge bin or conveyor. The rake re-enters into the flowing water to carry out the cleaning process.

Key Features & Advantages of Multi Rake Bar Screen are:

- 1. Ideal for deep channels

- 2. Efficiently screens in changing water levels

- 3. Can handle a high volume of inflow

- 4. Simple mechanism, easy to install and operate

- 5. Automatic cleaning – based on time or level sensor activation

- 6. Requires minimum intervention

- 7. Low maintenance

- 8. Compact robust design and construction

- 9. Prevents clogging

The Multi rake Bar Screen design prevents it from clogging. This feature makes it superior to other screening methods.

Why Doesn’t the Multi-rake Bar Screen Clog?

The screening process essentially restricts debris on the surface of the screen. In Multi rake Bar Screens, the debris is retained on the surface of inclined bars. These bars are cleaned with the help of chain-mounted rakes. Multiple rakes clean the bar screen from the front side of the screen – unclog the screen. The rakes carrying debris are cleaned with the help of a wiper and sent to the waste bin or a conveyor. The rate at which the rakes move (cycle time) is set either on a time interval basis or level sensors.

For influent containing large amounts of debris, the number of rakes can be increased. Also, the cycle time can be increased to ensure that the inclined bars are clean and not clogged. The automatic, continuous cleaning enables optimum performance, minimal labor requirement, and high-capacity screening. The rake and comb plates are independently replaceable ensuring easy maintenance and a clog-free screen.

The Multi-rake Bar Screen is superior to other screens because of its unique design. Multi rake Bar Screen has no submerged sprockets. The design ensures zero friction between the chain and the frame of the bar screen. The debris is collected from the submerged part of the screen. The underneath collection of debris helps to avoid blockage and prevent the equipment from jamming and damage. The continuous mechanized cleaning guarantees an unclogged screen even during high flow rates.

The Multi rake Bar Screens are ideal for use in wastewater treatment, headworks, sewage treatment, floating trash removal, and food processing.

Frequently Asked Questions

Q.1 Where are mechanical bar screens used?

A. Mechanical bar screens are commonly used in municipal and industrial wastewater treatment plants, stormwater systems, and water intake facilities to protect downstream equipment and processes from damage and clogging.

Q.2 Can manual bar screens handle all types of debris?

A. Manual bar screens are designed to remove large debris such as rags, plastics, and other solid waste. However, smaller particles may pass through and require additional filtration methods downstream.