Importance of Floating Decanter in the Clarification Process

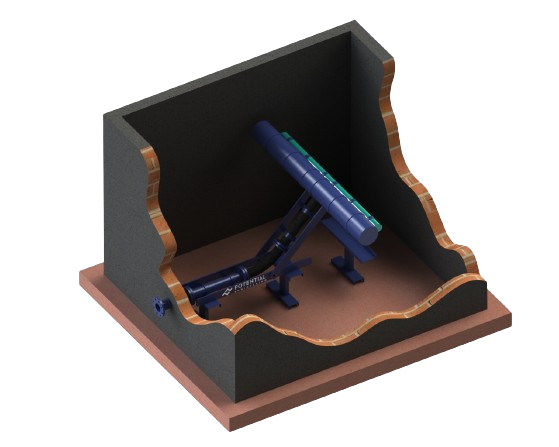

The floating decanter removes supernatant liquid from the basins. They are widely used in the clarification processes. They find application in sequential batch reactors, equalization tanks, aerobic digester thickening, water holding basins, etc. The floating decanters primarily utilize a weir for decanting and a floating device for supporting the weir. The floating decanters are classified on the methods used to eliminate foam, scum, and solids, which are – air-filled decanters, mechanically closed decanters, and spring loaded NRVs.

Why is a Floating Decanter used in the Clarification Processes?

The floating decanters aid the clarification process and improve the overall treatment efficiency. One of the important aspects of a water or wastewater treatment plant is to separate solids and liquids, which subsequently undergo further treatment. The floating decanter plays a vital role in efficiently separating solids from liquids.

The floating decanter is placed beneath the surface of the water to draw only the water and eliminate floating debris, scum, and foam. The floating decanter’s design permits it to move upwards and downwards to maintain its position with the change in water levels. The movement ensures that, at all times the floating decanter withdraws water and prevents floating debris, scum, and foam.

In the clarification processes, the floating decanters facilitate the settling process, resulting in sludge thickening at the bottom of the settling tank, which further facilitates treatment before it is disposed-off. And the water drawn from the basin is free of suspended solids, floating debris, scum, and foam. The clarified water treatment process is less complex than water containing sludge, suspended solids, and floating debris. It also impacts the equipment and treatment costs. Hence, the decanting method is critical to a water, wastewater, or effluent treatment plant.

Benefits of a Floating Decanter in Clarification Processes

Now we know that the floating decanter separates solids and liquids efficiently, which is an important aspect of a treatment plant. But why floating decanters?

The answer to why floating decanters is found in its unique design features and benefits it offers, which are:

- • The floating decanter allows to drain of the tank in the top-down method while eliminating harmful vortexes

- • The floating feature of the decanter allows maximum distance between the withdrawal point and settled solids

- • The decanter floats vertically to adjust to the changing water levels

- • The float on a floating decanter can act as a baffle, preventing scum from being withdrawn during decanting

- • The design prevents over-decanting

- • It does not have electro-mechanical components, thus requires low maintenance

- • It can handle large volumes and changing water levels

- • The floating decanter material of construction is corrosion-resistant

- • It is safe to operate in a hazardous environment

The floating decanter has proved to be effective in the withdrawal of liquid, free from floating debris, and in producing a good sludge blanket at the bottom of the basin in the clarification process. Depending on the elimination method requirements a suitable floating decanter can be deployed.

We can conclude that the efficient, low maintenance, flexible floating decanters are ideal solid liquid separators for the clarification process.

Frequently Asked Questions

Q.1 Why are Boom Reels essential for managing oil spills?

A. Boom Reels are essential for managing oil spills because they facilitate the rapid deployment and retrieval of containment booms, allowing responders to contain and limit the spread of oil quickly. This efficiency enhances the overall effectiveness of spill response efforts, minimizing environmental impact.

Q.2 Can investing in adjustable weir gates reduce long-term operational costs?

A. Yes, investing in adjustable weir gates can reduce long-term operational costs by improving flow control and efficiency in water management systems. This adaptability minimizes energy use and maintenance needs, ultimately leading to cost savings over time.