Why Do We Need Different Types of Oil Skimmers?

A skimmer is a mechanical device designed to remove oil from the surface of water. They are used as oil spill response equipment and in industrial settings. The skimmer mainly works on the three principles, which are:

- • The density difference between oil and water,

- • Fluid properties of oil and water, and

- • The adhesion properties of oil and water

The skimmer plays an important role in oil removal in various industries. They are used for removing oil, grease, and fats.

Oil skimmers have gained importance in industrial settings primarily because they remove oil from water or mixture mechanically, without altering the physical or chemical properties of the water. They are commonly used to remove oils, grease, and fats prior to further treatment for environmental discharge compliance. Prior to oily water treatment, the use of an oil skimmer substantially improves oil separation efficiency resulting in high-quality waste water.

Skimmer Design and Mechanism

The skimmers mechanically separate oil from the water surface using a variety of mechanisms. The mechanism used to remove oil from the water surface includes an oleophilic system, a weir system, a slotted pipe, and a suction system. The skimmer systems are designed to efficiently remove oils of certain specifications, in certain conditions.

Oleophilic Oil Skimmers

The oleophilic oil skimmers employ materials having a greater affinity for oil than water. There are several types of oleophilic oil skimmers such as brush skimmer, belt skimmer, tube skimmer, disc skimmer, and drum skimmer. In all these types of oleophilic oil skimmers the skimming surface is rotated or pulled through the oil slick and the oil is scrapped or wiped off. The recovered oil is collected into a tank or pumped out. Oleophilic oil skimmers are highly efficient in recovering medium viscosity oils.

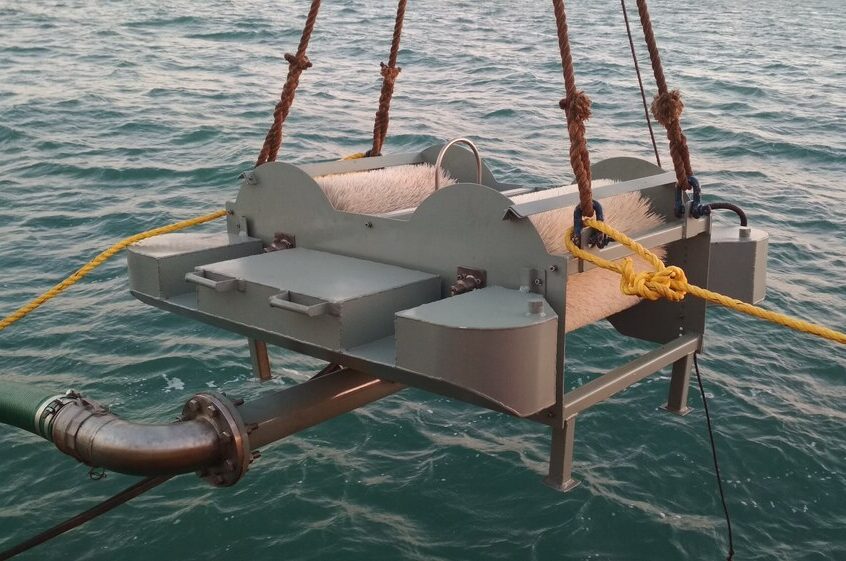

Brush Skimmer: The brush skimmer is a versatile oil skimmer, as different brush sizes can be used to recover light, medium, or heavy oils. It is a floating device that equips a rotating brush as an adhesion surface. The brush skimmer can be fixed for a small area or, can float across a large surface area while recovering oils.

Drum Skimmer: The drum skimmer is a rotary oil skimmer, similar to a brush skimmer. The drum is the oleophilic surface. The drum can either be fixed or floating across the water’s surface. It is ideal for recovering medium-viscosity oils.

Belt Skimmers: The belt skimmers are fixed-position, mounted on a vessel/tank. They have high recovery efficiency and a good recovery rate. They are effective in recovering medium to heavy oils. A belt is partially submerged into the mixture, which rotates in a closed loop to recover oil.

Tube Skimmer: Similar to the belt and disc skimmers, the tube skimmer is also a fixed position skimmer. It employs a tube as the oleophilic surface. The advantage a tube skimmer has over a belt and disc skimmer is that it covers a large surface area, as the tube floats across the surface of the fluid.

Disc Skimmer: The disc skimmer is similar to the belt skimmer. The oleophilic surface here is a disc instead of a belt. The disc skimmer is most effective in medium viscosity oils. They are popular as accessories for coolant tanks.

Each of the above mentioned oleophilic skimmers offers certain unique advantages and disadvantages based on their design and mechanism. The rotary skimmers such as drum and brush can cover a large surface area, whereas the fixed skimmers are bound to recover in a limited area. The rotary skimmers can get clogged as the moving parts come in contact with the fluid. Whereas, in the case of fixed skimmers the moving parts are not in contact with the fluid.

In the fixed-position skimmer, the tube skimmer design enables it to cover a larger surface area when compared to the belt, or disc skimmer. The adhesion properties of each oleophilic surface vary giving them their unique identity. The installation, operation, and maintenance of each of these skimmers vary. The operational capacity and oil recovery efficiency also vary, making them ideal for specific applications.

Non-oleophilic Skimmers

Suction skimmer: The suction skimmer employs an air suction system to recover oil from the water surface. The suction skimmer is ideal for use in calm waters, during oil pills. The suction mechanism of the skimmer results in a high proportion of water collection along with oil recovery, requiring further treatment.

The suction skimmer is also used in closed tanks and industrial applications. These suction skimmers are known as floating suction oil skimmers. The floating suctions self-repositions to the liquid level in the tank. Suction depth can be set and fine-tuned to accommodate aggressive surface suction and underneath a foam layer to remove the top layer of oily water. These floating suction oil skimmers are ideal for use in AFTs.

Gravity Skimmer: Weir skimmers and slotted pipe skimmers work on the principle of gravity. These skimmers selectively recover oil from the surface of the water.

The weir skimmer comprises floats and a self-adjusting weir mouth. The lip of the weir mouth is positioned at or slightly below the surface of the liquid to enable the flow of oil into the weir.

In the case of a slotted pipe, a rotary tube with a horizontal ‘C’ shape is mounted on the top of a tank to collect floating oil, scum, debris, etc. The pipe is positioned at the end of the tank in the direction of the flow. The pipe is rotated, slots facing in the direction of the flow, just at or below the surface of the liquid to allow oil, and floating contaminants to fall into the pipe.

Weir skimmers can be across the water surface whereas the slotted pipe is fixed. Both skimmers efficiently recover oils, contaminants, and floating debris.

Each of the oil skimmers has different requirements and offers different advantages. These oil skimmers prove to be highly effective in combination with certain applications. For example, a gravity-based skimmer enables fast recovery but may contain a high proportion of water, which can be further treated with the help of an oleophilic skimmer. A belt skimmer in combination with a weir skimmer can be more effective in recovering highly emulsified fuel oil.

Based on the oil viscosity, output parameters, environment, and fluid properties an appropriate oil removal system can be designed using the skimmers. The skimmers are not only efficient, cost-effective, and easy to operate and maintain but they also play a crucial role in safeguarding the environment by mitigating the oil levels in wastewater, recovering oils, and reducing water wastage.

Frequently Asked Questions

Q.1 Where can tube oil skimmers be used?

A. Tube oil skimmers are commonly used in various environments, including industrial facilities, marinas, oil refineries, and wastewater treatment plants. They are ideal for any location where oil spills or surface contamination may occur.

Q.2 What are the advantages of using a brush oil skimmer?

A. Brush oil skimmers are highly effective at removing oil from water, helping to reduce environmental pollution and protect aquatic ecosystems. They are durable, efficient, and can operate continuously, making them suitable for both large and small-scale applications.