How Do Slotted Pipes Improve Oil Removal?

Oil removal from wastewater is a common challenge faced by various Industries. Oil and gas, marine and shipping, metalworking and manufacturing, automotive and transportation, food processing, mining and mineral processing, and chemical and petrochemical manufacturing are some of the industries that produce a significantly large amount of oily wastewater.

Often complex mixtures of contaminants in wastewater make treatment a critical aspect of the business processes. To address the challenge industries, use a combination of technologies that are efficient, sustainable, and cost-effective for oil removal and separation from wastewater. One of the popular technologies for removing oil from wastewater is gravity separation technology. In this article, we will focus on oil-water separation using slotted pipe, a gravity-based separation equipment.

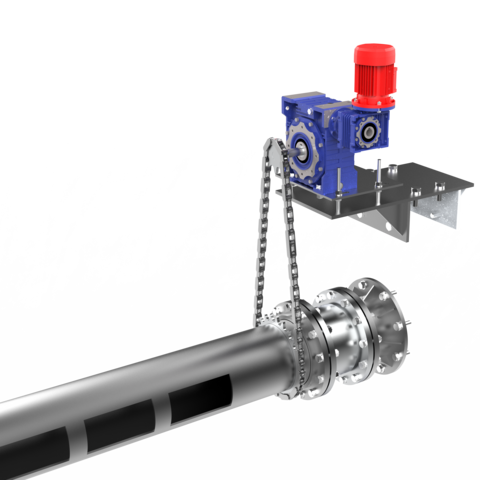

A slotted Pipe is a pipe with uniform slots along its length. The slots control the inflow and outflow of the top layer of water in a tank/basin. The slots in a slotted pipe allow water to flow through while preventing larger debris or particles from entering. However, it may be used to remove scum and small floating debris.

Typically, a slotted pipe is positioned horizontally at the end of the basin, facing the water flow. In operation the slots face the direction of the flow, allowing only the top layer of oil, water, scum, or floating debris to flow into it. The scum, oil, and debris collected in the pipe get discharged by gravity from the open flange end.

Slotted pipe plays a crucial role in enhancing oil removal. Its design improves the efficiency of oil-water separation systems. Let’s find out how.

− During operations water flows through the slots. The flow directs small oil droplets together, increasing their chances of colliding and combining. This coalescence creates larger oil droplets, which rise quickly to the surface due to buoyancy, making them easier to skim off or capture in the separator.

− Slotted pipe design can reduce the shear forces in the separator. Lower shear forces help maintain larger oil droplets intact, improve their buoyancy, and enhance their separation from water.

− Slotted pipes can filter out large debris and particulates before they reach other filtration or coalescing components in the separator. This prevents clogging and aids the protection of downstream equipment, enhancing the separator’s overall efficiency.

− In separators with coalescing media, slotted pipes distribute the flow evenly over the coalescing media. This uniform distribution ensures that oil droplets have an optimal chance to interact with the media and coalesce further, facilitating separation.

− Slotted pipes allow a calm entry and exit of water, minimizing any re-mixing of separated oil back into the water phase. This controlled outflow helps ensure that separated oil remains on the surface, ready for removal, and does not get re-entrained in the outflow.

In oil-water separators, slotted pipes enhance oil removal by enabling controlled flow, aiding droplet coalescence, and protecting downstream components of a wastewater treatment plant. They can handle oils of varying viscosity and flow rates efficiently. With slotted pipes, separators can operate more effectively, removing natural oils and hydrocarbons from wastewater before further treatment or discharge. Slotted pipes are easy to install, operate, and maintain making them a popular equipment for oil-water separation and removal.

Frequently Asked Questions

Q1.What features of slotted pipe oil skimmers ensure they are reliable and durable in challenging conditions?

A. Slotted pipe oil skimmers are durable with corrosion-resistant materials, efficient oil separation capabilities, and low maintenance needs, ensuring reliable performance in harsh environments.

Q2.Why should industries invest in oil skimmers for their facilities?

A. Industries should invest in oil skimmers to reduce pollution, improve environmental compliance, minimize operational downtime, and maintain efficient water treatment systems, ensuring sustainable practices.

Q3.How can adopting a brush oil skimmer reduce maintenance costs and downtime in your facility?

A. Adopting a brush oil skimmer helps reduce maintenance costs and downtime by effectively removing oils from water systems, minimizing the need for frequent cleaning, repairs, and system disruptions, leading to smoother operations.