A Guide to Choosing the Right Oil Water Separator for Your Business Needs

Businesses thrive hard to reach their full potential through increased efficiency to gain high profitability. Right processes, right equipment and smooth operations are some of the key factors to reach the full potential. In this article we will focus on one such equipment – oil water separator (OWS). Oil water separator finds application almost in all industries. A range of OWS are available in the market but not every OWS will fit your requirements.

Oil water separators vary in their design, working, and capacity to suit specific requirements. Identifying the right oil water separator for your business application is critical in improving the overall process performance. Here’s a guide to help you find the right fit:

Need

- • Industry standards: Different industries such as automotive, food processing, shipping, wastewater treatment, etc. have specific requirements for oil-water separation. The type and volume of oil contaminants in wastewater can vary greatly, so understanding your industry standards is essential.

- • Application: Determine the application, whether industrial wastewater treatment, emergency oil spill, AFTs, etc. Different OWS machines are optimized for different applications.

Compositions

- • Oil Type: Identify the type of oil being separated, whether it’s light oils, heavy oils, or emulsified oils.

- • Flow Rate and Volume: Measure the typical flow rate and total volume of wastewater that needs treatment. This will determine the capacity required.

- • Particle Size and Density: Consider the size and density of contaminants. Some separators are more effective for larger particles or certain densities.

Separator Type

- • Gravity Separators: Ideal for separating non-emulsified oils in a simple and low-maintenance setup. They rely on the difference in density between oil and water to naturally separate the two.

- Examples: API (American Petroleum Institute) Separators & Parallel Plate Separators.

- Applications: Used in industrial facilities, wastewater treatment plants, and oil refineries.

- • Coalescing Plate Separators: These increase the surface area for small oil droplets to combine and float to the surface for easy removal, often used in medium-sized facilities. These use plates or surfaces to encourage small oil droplets to coalesce (combine) into larger ones, making them easier to separate. They are compact and have high efficiency for removing smaller oil droplets.

Applications: Commonly used in manufacturing plants, power stations, and automotive service facilities.

- • Centrifugal Separators: Best for heavy-duty operations where oil and water must be separated under higher pressures. They use centrifugal force to separate oil and water based on density differences. Effective for emulsified oils and mixed-density contaminants. Applications: Heavy industries like mining, marine, and drilling operations.

Efficiency and Environmental Standards

- • Look for separators that meet local environmental standards for wastewater discharge. Many governments and regions have strict discharge limits for oil content in wastewater.

- • Check the machine’s efficiency rating, often measured as percentage removal of oil from the water. Higher efficiency models are costlier but reduce maintenance and environmental risk over time.

Ease of Maintenance

- • Consider models with accessible parts for cleaning and maintenance. Some machines may require frequent filter changes or sludge disposal.

- • Look for options that offer automated maintenance features, such as self-cleaning filters or automated oil skimming.

Cost and Energy Consumption

- • Compare the initial purchase price with long-term operational costs, including maintenance, energy use, and potential waste disposal fees.

- • Energy-efficient models may have higher initial costs but can save significantly in the long run, especially in high-volume operations.

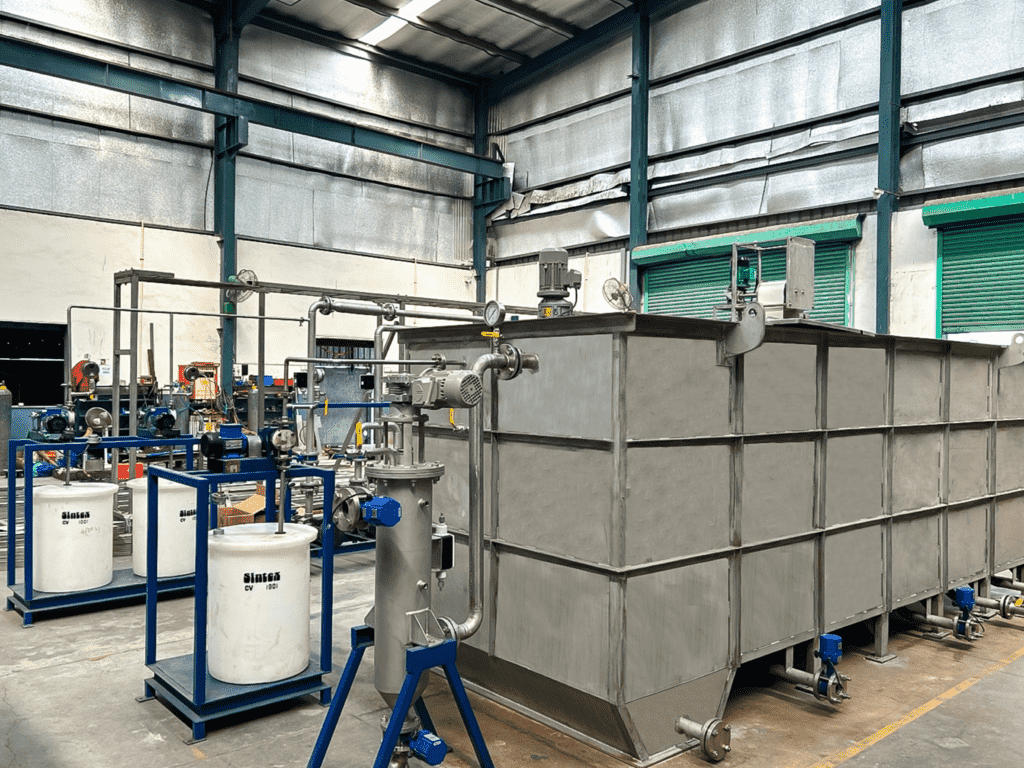

Space and Installation Requirements

- • Measure the available space in your facility, as some separators have large footprints or require specific layouts.

- • Consider how the separator will fit into your existing wastewater management system. Some models require additional tanks or equipment.

Vendor Support and Warranties

- • Look for vendors that provide robust support, including installation assistance, training, and long-term servicing options.

- • Review warranty options to ensure you’re protected against potential malfunctions or defects.

Advanced Features

- • Some machines offer smart controls or remote monitoring, allowing for easier management and adjustment based on real-time data.

The above points should help you in the selection of an oil-water separator machine that meets your business needs, complies with regulations, and fits within your budget.

Frequently Asked Questions

Q1.What factors influence the performance of a hydrocyclone separator?

A. The performance of a hydrocyclone separator is influenced by several factors, including the slurry’s flow rate, particle size distribution, viscosity, pressure, and the diameter and design of the hydrocyclone itself.

Q2.What is the typical output quality after using a TPI oil separator?

A. The TPI oil separator can produce effluent with very low oil content, often meeting environmental standards for discharge or reuse. The output quality depends on factors such as the type of oil being separated and the design of the separator.