Why Industrial Vacuum Systems Are Vital for Oil Spill Emergency Response

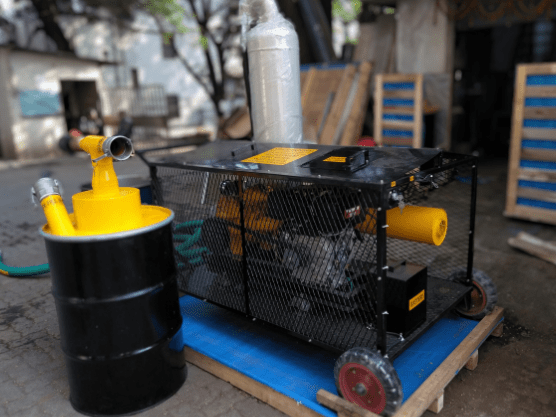

Oil spills remain one of the most challenging environmental emergencies for industries handling petroleum products. Rapid containment and safe recovery are crucial—not only to protect ecosystems but also to restore operational continuity. This is where industrial vacuum systems step in as the backbone of modern spill response strategies, offering unmatched speed, safety, and efficiency.

In today’s sustainability-focused industrial landscape, organizations are increasingly adopting advanced oil spill vacuum technologies that align with global environmental standards and minimize ecological damage. This blog explores why vacuum-based systems have become vital in emergency oil spill response and how they transform spill management across sectors.

What Makes Industrial Vacuum Systems Essential for Quick Oil Spill Cleanup?

Fast recovery is the top priority during any spill event. Conventional mechanical cleanup tools often struggle with sludge, heavy oil, debris, and complex spill conditions. Industrial vacuum systems solve this with precision-engineered suction power designed for emergency conditions.

1. High-Speed Recovery for Thick and Heavy Oils

Industrial spills often involve viscous hydrocarbons, emulsified mixtures, or oil-water sludge. Vacuum systems provide high airflow and suction that allow responders to collect:

Heavy crude oils

Floating sludge

Oil-water mixtures

Contaminated solids and debris

This makes them far more efficient than skimmers alone.

2. Minimal Downtime During Cleanup

Vacuum systems reduce the time required to stabilize the spill site. Faster cleanup means:

Lower contamination spread

Reduced environmental fines

Faster restart of industrial operations

Lower cost of manpower and containment

3. Versatility Across Surfaces and Terrains

Oil spills rarely happen on predictable surfaces. Vacuum systems can recover oil from:

Concrete or hard floors

Soil and gravel

Water bodies

Confined industrial spaces

Whether the spill occurs near tanks, pipelines, marine docks, or wastewater pits, vacuum units adapt immediately.

Why Industrial Vacuum Systems Are the Safest Choice for Oil Spill Recovery?

Safety is a non-negotiable factor during spill response. Oil spills carry fire risks, toxic fumes, and slipping hazards. Vacuum systems help responders manage these risks with engineered safeguards.

1. Closed-Loop Recovery Minimizes Exposure

Unlike manual oil collection, vacuum-based systems operate in a sealed, closed-loop transfer, preventing:

Vapor escape

Splash hazards

Worker exposure to harmful fumes

Ignition risks from volatile hydrocarbons

This ensures compliance with international safety standards such as API and OSHA.

2. Intrinsically Safe Equipment Options

Industrial vacuum systems used for oil spill recovery often come with:

ATEX-certified components

Anti-static hoses

Explosion-proof motors

Spark-resistant materials

These features significantly reduce the risk of ignition during spill operations.

3. Reduced Environmental Damage

By preventing oil seepage into soil, groundwater, or stormwater drains, vacuum systems support environmentally responsible recovery.

How Do Industrial Vacuum Systems Support Emergency Spill Response?

Emergency response teams rely on equipment that’s quick to deploy, highly mobile, and capable of handling unpredictable conditions. Vacuum-based systems check every box.

1. Rapid Deployment During Emergencies

Vacuum units—especially trailer-mounted or truck-mounted versions—can be mobilized within minutes. This allows responders to quickly:

Contain the spill

Prevent spread to waterways

Begin suction-based recovery immediately

2. Compatibility with Multiple Spill Response Tools

Vacuum systems integrate seamlessly with:

Skimmers

Temporary storage tanks

Transfer pumps

Barriers and booms

This multi-tool compatibility strengthens overall response efficiency.

3. Support in Wastewater & Sludge Management

Beyond direct spill cleanup, these systems play a major role in post-spill wastewater treatment—particularly when dealing with oily sludge.

For industries using scraper wastewater treatment systems, vacuum units help remove accumulated sludge, improving efficiency and reducing maintenance downtime.

Conclusion

Industrial vacuum systems have become indispensable for emergency oil spill response thanks to their unmatched speed, safety, and versatility. From preventing environmental contamination to reducing downtime and ensuring worker safety, they offer a modern, sustainable approach to spill recovery.

Potential Engineering & Robotics continues to innovate in this sector, delivering advanced vacuum solutions engineered for real-world industrial challenges.

If your facility handles hazardous liquids, investing in high-performance vacuum technology is one of the most responsible steps you can take for environmental protection and operational resilience.

Frequently Asked Questions (FAQs)

Q1. What makes industrial vacuum systems essential for quick oil spill cleanup?

A: Industrial vacuum systems offer powerful suction, fast deployment, and the ability to recover viscous oils and contaminated solids. Their speed and versatility significantly reduce spill spread and cleanup time.

Q2. Why are industrial vacuum systems the safest choice for oil spill recovery?

A: These systems feature closed-loop suction, explosion-proof components, and anti-static hoses, reducing worker exposure and ignition risks. This ensures safer, more controlled oil spill recovery.

Q3. How do industrial vacuum systems support emergency spill response?

A: They enable rapid deployment, seamless integration with other spill tools, and efficient handling of oily sludge and wastewater—making them a core component of emergency response plans.

Q4.Can vacuum systems handle both land and marine oil spills?

A: Yes. Industrial vacuum systems can remove oil from soil, concrete, docks, shorelines, and even floating layers on water, making them adaptable for diverse spill scenarios.

Q5. Are industrial vacuum systems suitable for hazardous waste handling?

A: Absolutely. With enclosed transfer systems and ATEX-certified safety features, they handle hazardous, flammable, and toxic liquids with minimal risk.