How Do Honeycomb Screens Protect Water Intake Systems From Debris Damage?

Water intake systems, which guarantee constant flow for cooling, processing, and treatment applications, are the unsung heroes of industrial operations. However, everything from pumps to downstream equipment is at risk when debris gets into these systems unchecked.

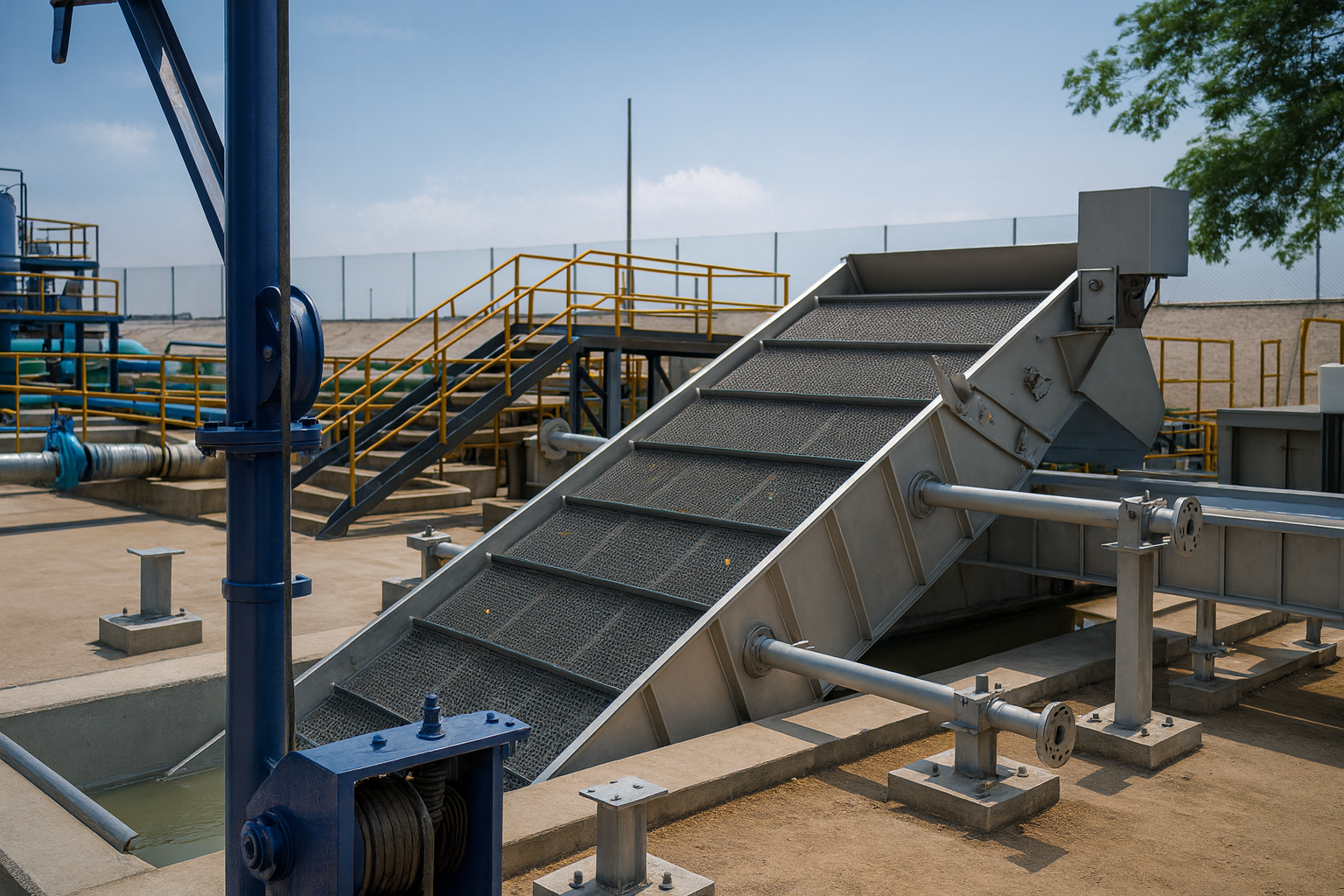

As the first line of defense, honeycomb screens provide effective, portable, and long-lasting filtration at the intake point.

In this blog, we explore what happens when debris enters pumping systems without a honeycomb screen, how a honeycomb screen prevents equipment damage, and how proper installation improves filtration efficiency.

What Happens When Debris Enters Pumping Systems Without a Honeycomb Screen?

When a water intake lacks proper screening, debris ranging from leaves and plastics to aquatic organisms can enter the pumping system. This creates a chain reaction of mechanical issues that escalate over time.

1. Pump Clogging and Reduced Flow Rates

Debris builds up inside pump impellers and valves, restricting the flow of water. This leads to:

Increased pump workload

Higher energy consumption

Lower operational efficiency

In extreme cases, pumps may overheat or shut down entirely.

2. Abrasion and Wear on Critical Components

Solid particles scrape against metal surfaces, accelerating wear on:

Impellers

Bearings

Seals

This premature wear results in frequent maintenance cycles and unexpected downtime.

3. Cavitation and System Imbalance

Debris buildup creates turbulent flow, which may trigger cavitation — the formation of vapor bubbles that collapse violently inside the pump.

Cavitation causes:

Structural damage

Loss of pumping capacity

Increased vibration and noise

4. Higher Maintenance and Energy Costs

Systems without a honeycomb screen face constant blockages. Operators must frequently halt operations, clear debris, and restart equipment — a process that increases labor and power consumption.

How Does a Honeycomb Screen Prevent Equipment Damage in Water Intake Systems?

A honeycomb screen is engineered with a hexagonal grid that provides superior structural strength and exceptional filtration capability. Its geometry allows high open area while ensuring uniform debris blocking.

1. Multi-Layer Defense Against Floating and Settled Debris

The screen traps:

Leaves

Sticks

Aquatic plants

Plastics

By preventing these contaminants from entering the intake line, the screen minimizes mechanical stress on pumps and equipment.

2. Protection of Downstream Treatment Units

A steady, debris-free water supply is crucial for downstream equipment like filters, aerators, and clarifiers.

Honeycomb screens reduce the frequency of:

Emergency shutdowns

Overload damage

Manual cleaning cycles

How Does Proper Honeycomb Screen Installation Improve Filtration Efficiency?

Even a high-quality screen underperforms if installed incorrectly. Proper installation ensures structural integrity, optimal water flow, and long-term performance.

1. Correct Positioning in the Intake Flow Path

Honeycomb screens must be placed at the correct angle and depth:

Too deep → unnecessary pressure load

Too shallow → missed debris capture

Correct positioning prevents bypass flow and maximizes filtration area.

Many facilities pair honeycomb screens with bar rack water treatment systems to create a multi-stage debris removal setup that enhances both intake protection and overall filtration efficiency.

2. Ensuring Structural Stability

A well-installed frame ensures:

Zero vibration under high flow

Stable water velocity across the grid

Long-term durability under constant pressure

This minimizes the risk of deformation or tearing.

3. Maximizing Filtration Surface Area

Optimal installation maintains full exposure to the water column.

Benefits include:

Better debris retention

Higher flow-through capacity

Lower chances of suction-side blockage

4. Easy Access for Maintenance

Screens installed with the right clearance allow rapid cleaning. This supports sustainable operation by keeping:

Energy consumption low

Maintenance frequency predictable

Filtration performance consistent

Conclusion

Honeycomb screens are essential for safeguarding water intake systems from debris-related damage. They improve pump reliability, minimize downtime, and enable smoother downstream operations. With proper installation, they deliver high-efficiency filtration while supporting sustainable, long-term water management.

Potential Engineering continues to provide robust, eco-conscious solutions that protect both equipment and the environment.

FAQs

Q1. What happens when debris enters pumping systems without a honeycomb screen?

A: When there is no screening in place, debris clogs pumps, reduces flow rates, increases energy usage, and accelerates mechanical wear. This leads to frequent breakdowns and costly repairs.

Q2. How does a honeycomb screen prevent equipment damage in water intake systems?

A: A honeycomb screen blocks debris at the intake point and safeguards downstream units. Its hexagonal structure ensures balanced flow distribution and long-term durability.

Q3. How does proper honeycomb screen installation improve filtration efficiency?

A: Correct installation ensures optimal positioning, maximum surface exposure, stable flow, and easy maintenance access. This results in better debris capture and consistent filtration performance over time.

Q4. Can honeycomb screens reduce operational costs in pumping systems?

A: Yes. By preventing clogging and reducing wear, honeycomb screens help maintain stable pump performance, lower energy use, and minimize unplanned maintenance costs.

Q5. Are honeycomb screens better than manual screens?

A: Honeycomb screens offer higher structural strength and more uniform debris filtration compared to typical manual screens. They are ideal for high-flow industrial intake applications.