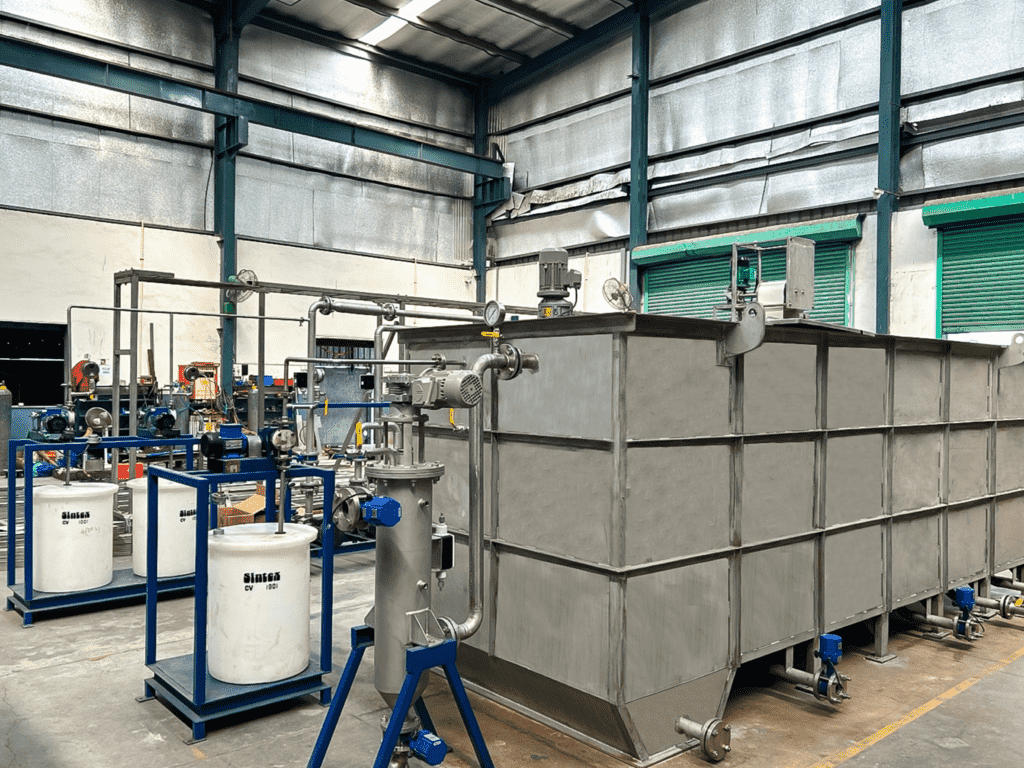

Above the Ground Rectangular Tank Oil Water Separator

The above-the-ground rectangular tank oil water separator (OWS) is designed to remove free-floating oil, grease, and settleable solids from oil/water mixtures, effluent, and wastewater. It finds application in industrial and commercial setups.

Design

The above-the-ground rectangular tank oil water separator is a compact, packaged unit. It mainly consists of a primary & secondary separator chamber and an effluent discharge chamber. It is equipped with a coalescer separator for oil separation. The design of the above-the-ground rectangular tank oil water separator has no moving parts, enables large flow rates, optimized sedimentation, enhanced retention time, and provides a large surface area for oil separation.

Working

The wastewater/effluent flows in the stationary OWS from the inlet. At the inlet, the wastewater gets directed over a baffle. The baffle plays three important roles in oil-water separation. It reduces the velocity and turbulence of the incoming water. The wastewater flow is redirected downward. It reduces and distributes the flow evenly.

The contaminants such as settleable solids, settle at the bottom of the tank in the primary chamber. Whereas, concentrated oil droplets rise to the surface.

The oily water enters the secondary chamber to pass through the inclined coalescer separator. Coalescer separator intercepts tiny droplets of oil to form a giant droplet, that floats to the surface. At the same time, floating solids are intercepted on the flat top surface of the inclined coalescer plates. These floating solids slide downward into the sludge collection area. Here, the solids flow downward and oil droplets rise upwards to the surface of the water.

The difference in gravity of oil and water enables the removal of oil from the top surface. With the help of a suitable oil skimmer, oil is removed from the top surface and oil-free water is discharged from the bottom of the tank. The oil-free wastewater is either discharged as per the guidelines or recycled for reuse. Similarly, oil recovered from the surface of the wastewater is either recycled or disposed of as per the disposal guidelines.

Features & Advantages:

The above-the-ground rectangular tank OWS can be custom-designed. This OWS can be equipped with an effluent pump-out chamber, an oil storage chamber, and an added oleophilic filter media. Based on the requirement the features may change. Some of the standard features and advantages of the above-the-ground rectangular tank OWS are:

- • High Capacity

- • Compact, packaged design

- • Double-wall steel tank

- • Coalescer separator

- • No moving parts

- • Safe for operation in hazardous areas

- • Does not use any chemicals for separation

- • Removable vapour-tight cover

- • Easy to maintain

- • Automated system

- • Effluent outlet

- • Waste oil level sensor

- • Low maintenance cost

- • High efficiency

Applications

The packaged above-the-ground rectangular tank oil water separators are ideal for use in:

- • Facility vehicle services

- • Process water

- • Environmental Remediation

- • Oil terminals

- • Railroads yards

- • Grinding and milling machinery

- • Electric utilities and power plants

- • Vehicle and equipment washing

- • Stormwater

The above-the-ground rectangular tank oil water separator is a single unit delivering high-efficiency oil water separation. The unit does not have any moving parts and does not require power. The efficiency of this OWS is dependent on various parameters. For optimum performance of OWS, the key design parameters to be considered are inlet flow rate, specific gravity of contaminants, concentration, oil storage capacity, temperature, and required effluent quality.

The simple design, and effective separation of free oil, dispersed oil, and settleable solids have made the above-the-ground rectangular tank oil water separator ideal for use in various industrial and commercial applications. The recovered oil and water from the OWS can be recycled or discharged as per the guidelines set by the authorities. This single-unit tank is easy to operate and requires low maintenance. It can be customized as per your site requirements and proves to be value for money.

Frequently Asked Questions

Q.1 How can a tank cleaning robot improve efficiency and safety?

A. A tank cleaning robot can significantly improve efficiency and safety by automating the cleaning process, reducing human exposure to hazardous environments, and ensuring thorough and consistent cleaning results.

Q.2 How effective are oil water separator machines in reducing environmental pollution?

A. Oil water separator machines are highly effective tools in mitigating environmental pollution by efficiently separating oil from water, ensuring cleaner discharge into the environment.

Q.3 What makes tpi oil water separators superior to other separation methods?

A. TPI oil water separators are superior to other separation methods due to their advanced design, high efficiency, and reliable performance in various industrial applications.