Advantages of a Non-metallic Chain Scraper System – An Overview

The Non-metallic chain scraper is an advanced scrapping system, compared to the traditional steel chain scraper. This chain scraper system uses non-metallic materials, is highly efficient, and is suitable for rectangular tanks. It is ideal for use in wastewater treatment plants, water treatment plants, desalination plants, oil removal applications, and in various industries such as oil & gas, pulp & paper, chemicals, food & beverage, etc.

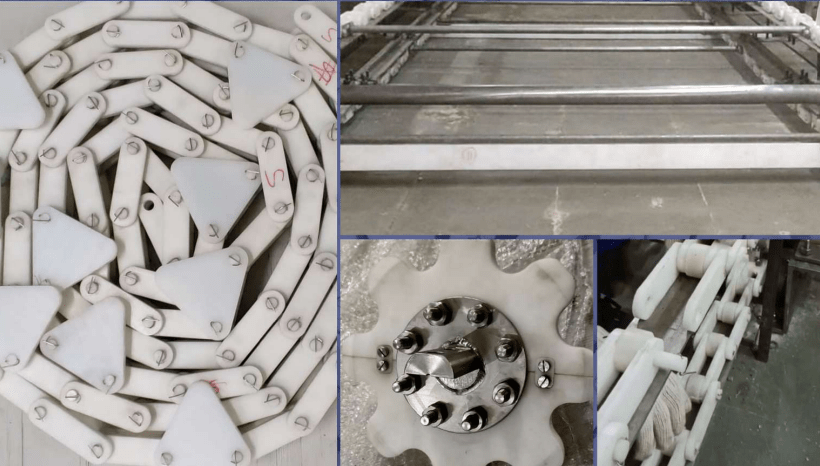

The non-metallic chain scraper working is similar to the conventional metal chain scraper system. The shift to non-metallic chain scraper from metal chain scraper has been welcomed due to the advantages it offers from the cost, installation, working, maintenance, and efficiency perspective. Further on, we will discuss some of the key benefits of using a non-metallic chain scraper.

The non-metallic chain scraper system is economical compared to the metal chain scraper. It is anti-corrosive hence, has a long life in a corrosive environment compared to the metal chain scraper system. The non-metallic scraper system delivers up to 10 times more service life than a metallic chain scraper.

The Non-metallic chain scraper is lightweight, it considerably reduces the load, and it requires less energy to rotate in comparison to the metal chain scraper, thereby reducing energy consumption. Also, it is easy to install and maintain due to its lightweight.

The non-metallic chain scraper has a good strength and weight ratio ideal for long-width tanks. This ratio ensures stiffness and resistance to bends. Also, the movement of the non-metallic chain scraper is less noisy compared to the metal chain scraper.

The components and spare parts of a non-metallic chain scraper are durable, lightweight, and easily available. The strength of the non-metallic chain collector is almost equivalent to cast or SS chain even though it is extremely lightweight compared to either of them. This makes installation and maintenance easy and cost-effective. Whereas, in the case of a metallic chain scraper system at certain sites, a crane is required for installation.

The maintenance of the non-metallic chain scraper does not require regular painting as it is rust-free. It is easy to work on because it is lightweight and rust-proof.

The non-metallic chain scrapers’ working and maintenance ensure a short-duration return on investment (ROI).

The non-metallic chain scraper system is offered as per the specific scraping requirements, which are:

- 1. Two-shaft top scraping

- 2. Two-shaft bottom scraping

- 3. Three-shaft bottom scraping

- 4. Four shaft top & bottom scraping

The non-metallic chain scraper system is a user-friendly solution for water treatment, wastewater treatment, DAF, API oil-water separator, stormwater treatment, etc. The non-metallic chain systems’ endless chain conveyor is reliable for applications such as sludge chain scraper, scum chain scraper, and sludge & scum chain scraper.

The non-metallic chain scraper can be partially retrofitted. Its features enable fast installation and easy adaptation to an existing chain and flight system. The monitoring system offers monitoring of flight alignment, sprocket motion, and flight motion, which aids in the healthy maintenance of a non-metallic chain scraper system.

The non-metallic chain scraper is the most suitable system for toxic media, which may contain hazardous and corrosive substances. The system is offered in a wide range of material of construction (MOC) such as Delrin, nylon, glass-filled nylon, UHMWPE, FRP, GRP, polyurethane, etc.

We can conclude that the non-metallic chain scraper system is a reliable, economical, and adaptive fight and chain scraper system for scum removal, sludge removal, grit removal, oil-water separation, and similar application for a rectangular tank.

Frequently Asked Questions

Q.1 Why are sludge and scum scraper systems essential for wastewater treatment?

A. Sludge and scum scraper systems are essential for wastewater treatment because they efficiently remove accumulated solids and floating debris, ensuring the smooth operation of the treatment process and preventing blockages and contamination in downstream systems.

Q.2 Why should you consider implementing a travelling bridge scraper system?

A. Implementing a traveling bridge scraper system enhances the efficiency and reliability of sludge removal in water treatment facilities, ensuring optimal operational performance and maintenance of hygiene standards.