An Overview of Hydraulic Driven Submersible Centrifugal Pumps

A hydraulic-driven submersible centrifugal pump is designed to pump liquid in a submerged state. The pump is completely placed in the liquid that is to be pumped. The hydraulic-driven submersible centrifugal pump pumps liquids such as wastewater, water, chemicals, oils, and soft solids.

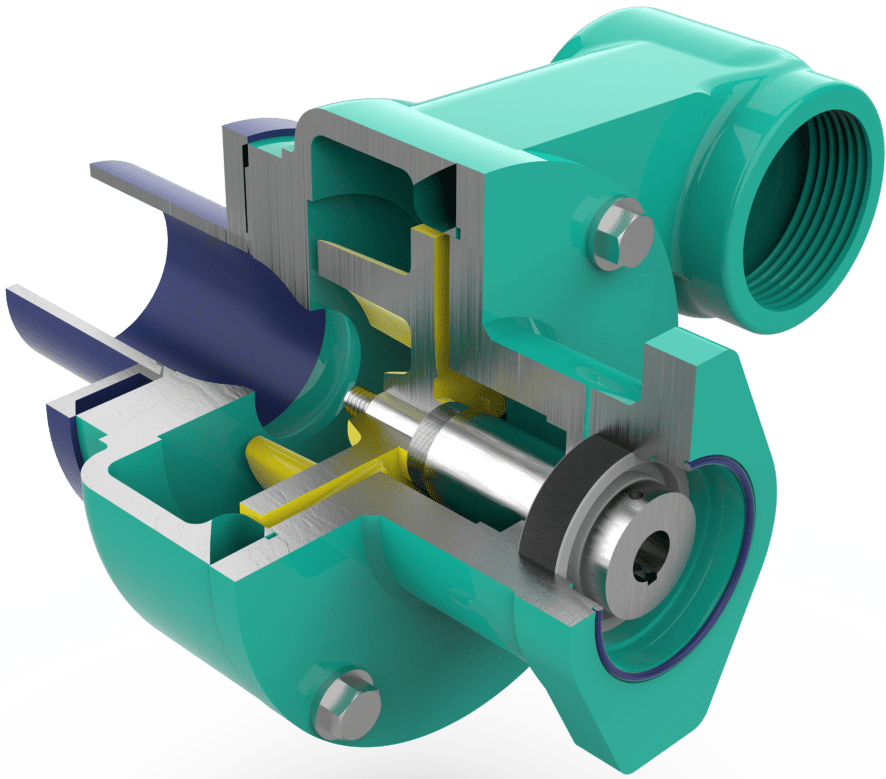

The hydraulic-driven submersible centrifugal pumps are self-priming, and driven by a hydraulic motor. The centrifugal pump is connected to the drive shaft to enable rotational movement. The liquid, on entering the pump moves outwards due to the centrifugal force. The liquid enters the pump casing due to the outwards movement. Here, the velocity is converted into pressure which forces the liquid to leave the pump. A fluid flow arises due to the pressure difference between the inlet and outlet pipe.

The hydraulic motor of the submersible centrifugal pump is compact, compared to electric and diesel motors. The hydraulic motor transmits power by moving fluid under pressure and converting it into mechanical energy. The movement of the fluid enables quick and easy speed adjustment between zero and maximum speed.

Applications of the hydraulic driven submersible centrifugal pumps are varied, some of which are:

- • Water & Wastewater: seawater, deep well water, irrigation water, slurries, and sewage is pumped

- • Oil Industry: to pump crude oil, mud, slurry, etc.

- • In open sump pumping the use of a hydraulic-driven submersible pump is ideal due to its high volume and high head capability.

- • Beverage industry: they are used to transfer bottled water, juice, and beverages.

- • Dairy industry: used to transfer dairy products – buttermilk, milk, milk products, etc.

- • Chemical industry: to transfer refrigerants and cryogenics

- • Pharma industry: to transfer liquids and soft solids

The hydraulic-driven submersible centrifugal pump is a positive-displacement pump that uses rotational motion to transfer liquids and soft solids from the pump inlet to the outlet. It has proved to improve operations in a wide array of applications. The operational superiority achieved with the use of a hydraulic-driven submersible centrifugal pump are:

Due to Hydraulic Motor:

- • Efficiency: mechanical power can be applied very efficiently due to the incompressible nature of hydraulic fluid. The force generated is applied to the target, which is almost 100%

- • The hydraulic motor has a smaller footprint compared to other types of motor, which is an important aspect in challenging spaces.

- • The hydraulic motor can be submerged.

- • Hydraulic motor operations eliminate electrical safety hazards such as electric shock, and explosion.

- • The power generation capacity of a hydraulic motor is ten times the amount of power produced by an electrical counterpart, in certain cases.

Due to Centrifugal Pump:

- • These pumps are versatile, reliable, and require low maintenance

- • The pump has less friction, is anti-corrosion, and energy-efficient

- • The centrifugal pump is non-pulsating, enabling smooth flow

- • No heat transfer from the motor

- • The absence of drive seals eliminated the risk of a leak

- • They are offered in a wide range of capacities

The hydraulic-driven submersible centrifugal pump is compact and versatile. It can be fastened directly into a flow line. It can be operated in hazardous areas. It efficiently pumps liquids and soft solids. Its design is simple, it is easy to install and operate.

The operational efficiency, user-friendliness, and versatility of a hydraulic-driven submersible centrifugal pump are the key factors for its wide adaptation across varied industries.

Frequently Asked Questions

Q.1 How can a hydraulic power unit improve your operational efficiency?

A. A hydraulic power unit can improve your operational efficiency by providing consistent and reliable power, reducing downtime, and enhancing the performance of your hydraulic systems.

Q.2 Why should you consider switching to an electric-driven hydraulic powerpack?

A. Switching to an electric-driven hydraulic powerpack offers increased efficiency, lower operating costs, reduced environmental impact, and quieter operation compared to traditional systems.