Diesel Powerpacks: Features, Components, Safety, and Their Role in Industrial Applications

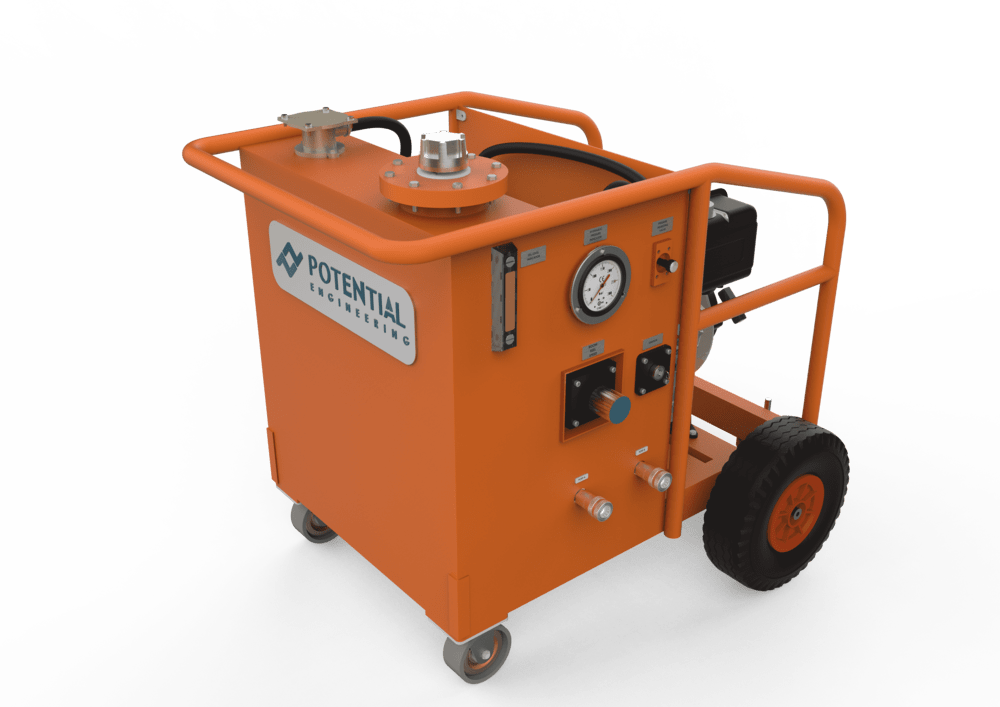

Diesel-driven powerpacks are compact, self-contained units designed to provide hydraulic power in locations where electricity is unavailable. These powerpacks combine a diesel engine with a hydraulic pump to generate hydraulic energy to power equipment and machinery.

Diesel-driven hydraulic powerpacks are known for their high performance, these powerpacks excel in rugged and remote environments. Built to withstand extreme conditions. The diesel powerpacks offer a reliable and efficient power source for lifting, drilling, and operating heavy-duty machinery. They equip critical components like a diesel engine, hydraulic pump, cooling system, and control panel. Diesel powerpacks are versatile, durable, and invaluable for demanding industrial applications.

Features of Diesel-driven Powerpacks

Diesel powerpacks are the preferred choice for industrial applications due to several key factors, which are:

– Fuel Efficiency: Diesel engines are known for their superior fuel economy, making them cost-effective for long-term use. Their ability to deliver more power per liter of fuel ensures optimal performance without excessive operating costs.

– Durability and Longevity: Built to withstand tough environments, diesel powerpacks are highly durable. Their sturdy construction allows them to operate effectively in extreme temperatures, dusty environments, and remote locations.

– High Torque Output: Diesel engines produce higher torque at lower RPMs, making them suitable for heavy-duty tasks such as powering hydraulic machinery, pumps, and compressors.

– Versatility: Diesel powerpacks can be customized to suit specific industrial needs, including mobile and stationary applications. This adaptability makes them a versatile solution for industries like oil and gas, military, mining, agriculture, construction, etc.

– Reliability in Remote Locations: Industrial operations in remote areas often lack access to a stable power grid. Diesel powerpacks provide a dependable source of power, ensuring uninterrupted operations.

– Multiple Circuits: Powerpacks can be designed with multiple hydraulic circuits to meet specific system requirements, offering enhanced flexibility for various industrial applications.

– Customizable Features: Diesel powerpacks can be equipped with safety and operational features such as spark arrestors, automatic low hydraulic oil shutdown systems, engine overspeed protection systems, high exhaust temperature shutdown systems, and low lube oil protection systems, ensuring reliability and safety.

Key Components of Diesel Powerpacks

A diesel powerpack is composed of several essential components, each contributing to its overall functionality:

– Diesel Engine: The heart of the powerpack, the engine converts fuel into mechanical energy, driving the entire system.

– Hydraulic Pump: Often paired with the engine, the hydraulic pump converts mechanical energy into hydraulic energy to power machinery.

– Cooling System: To prevent overheating, the cooling system regulates the engine’s temperature, ensuring consistent performance.

– Fuel Tank: The fuel tank stores diesel, providing the engine with the necessary fuel supply to operate efficiently.

– Control Panel: The control panel allows operators to monitor and control the powerpack’s performance – speed, pressure, and temperature settings.

– Filtration System: This system ensures clean fuel and oil flow, reducing wear and tear on engine components and extending the powerpack’s lifespan.

Safety Measures

Safety is paramount when operating diesel powerpacks, especially in industrial environments. Key safety measures include:

– Regular Maintenance: Conduct routine inspections and servicing to identify potential issues such as leaks, worn-out parts, or clogged filters. Preventive maintenance ensures the powerpack remains in optimal working condition.

– Proper Ventilation: Diesel engines emit exhaust gases, including carbon monoxide. Ensure the powerpack is operated in a well-ventilated area to prevent the buildup of harmful fumes.

– Operator Training: Operators should be adequately trained to handle the powerpack, including starting, stopping, and troubleshooting. Proper training reduces the risk of accidents and equipment damage.

– Compliance with Safety Standards: Adhere to industry-specific safety regulations and standards to ensure safe operation. Use appropriate personal protective equipment (PPE) and follow safety protocols.

– Emergency Shutdown System: Equip the powerpack with an emergency shutdown mechanism to halt operations immediately in case of a malfunction or safety hazard.

Diesel powerpacks are indispensable in industrial applications, offering unmatched efficiency, durability, and reliability. Their ability to power heavy-duty equipment and operate in remote locations makes them a preferred choice for industries worldwide. By understanding their components and adhering to safety measures, businesses can maximize the benefits of diesel powerpacks while ensuring safe and efficient operations.

As industries evolve, diesel powerpacks’ role continues to expand, driven by technological advancements that improve performance and environmental sustainability. Whether for construction, mining, or manufacturing, diesel powerpacks remain a vital tool for modern industry.

Frequently Asked Questions (FAQs)

Q.1 What Applications Are Electric Hydraulic Power Packs Used For?

A. Electric hydraulic power packs are commonly used in industries such as manufacturing, construction, automotive, agriculture, and material handling for powering hydraulic machinery and equipment.

Q.2 What Are the Key Features to Look for in a Hydraulic Submersible Pump?

A. Key features of a Hydraulic Submersible Pump include the pump’s power rating, maximum depth it can operate at, discharge capacity, build quality (especially corrosion resistance), and ease of maintenance.