First Line of Defence: The Importance of Pre-Treatment in Wastewater Treatment Plants

Wastewater originates from a variety of sources, which includes domestic, commercial establishments, industries, and stormwater runoff, and typically contains a mix of physical, chemical, and biological contaminants. Effective wastewater treatment is essential to protect public health, preserve aquatic ecosystems, and ensure regulatory compliance. However, before wastewater enters the main treatment systems, it must first undergo pre-treatment—a critical stage that removes large solids, oils, grit, and other harmful materials that can damage or disrupt downstream processes. Understanding the role and benefits of pre-treatment is key to designing efficient and reliable wastewater treatment systems.

Pre-treatment is the initial phase in wastewater treatment, designed to remove coarse and harmful materials that can interfere with downstream processes. It typically involves the following key steps:

- 1. Screening

Large objects such as plastics, rags, wood pieces, and other debris are removed using screens. This prevents clogging and mechanical damage to pumps and pipes.

- 2. Grit Removal

Sand, gravel, and other heavy inorganic particles are extracted in grit chambers or aerated grit tanks. If not removed, these abrasive materials can erode equipment and reduce the efficiency of treatment.

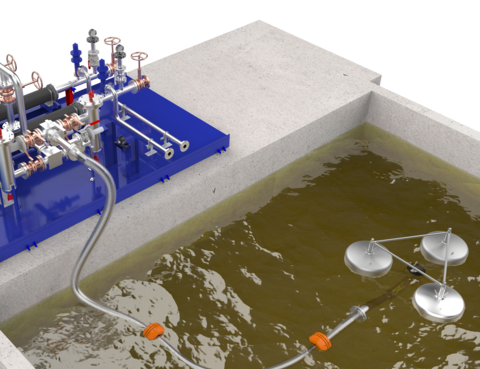

- 3.Oil and Grease Separation

Using skimming tanks or grease traps, floating fats, oils, and greases (FOGs) are separated from the water surface. FOGs can coat pipes and hinder biological treatment if left unchecked.

- 4. Equalization

In some facilities, flow equalization tanks are used to regulate the volume and pollutant load of incoming wastewater. This balances peaks in flow and concentration, ensuring consistent conditions for biological treatment downstream.

Each of these processes plays a foundational role in preparing the wastewater for more advanced physical, biological, or chemical treatment stages.

How pre-treatment contributes to the protection and longevity of downstream infrastructure?

Pre-treatment acts as the first line of defence for all wastewater treatment facilities; it plays a crucial role in safeguarding sensitive equipment and improving the overall efficiency of treatment systems, by:

- 1. Preventing Equipment Blockages and Damage

Large debris, plastics, and fibrous materials removed during screening can clog pumps, valves, and pipelines if left untreated. Grit and sand, if not separated, can cause excessive wear and tear on mechanical parts, leading to frequent maintenance or equipment failure.

- 2. Reducing Organic and Hydraulic Shock Loads

Flow equalization in pre-treatment buffers the system against sudden surges in wastewater volume or contaminant concentration. This prevents overloading of biological treatment reactors and ensures consistent operational conditions.

- 3. Minimizing Oil and Grease Accumulation

Floating oils and greases can form thick scum layers in aeration tanks, disrupt oxygen transfer, and foul equipment such as diffusers and sensors. Their early removal ensures smoother downstream biological and chemical processing.

- 4. Protecting Biological Treatment Processes

Many microorganisms used in secondary treatment are sensitive to toxic substances and extreme pH levels. Pre-treatment helps in neutralizing such harmful substances, improving the biological stability and treatment performance.

- 5. Enhancing System Efficiency and Cost Savings

With fewer breakdowns, reduced chemical usage, and stable process conditions, pre-treatment significantly reduces operational costs and extends the life span of downstream components.

In essence, an effective pre-treatment system not only protects infrastructure but also enables a more efficient and sustainable treatment process.

Common Contaminants

Wastewater entering treatment plants contains a wide variety of contaminants, depending on its source—domestic, commercial, industrial, or stormwater. The most common contaminants addressed during pre-treatment include:

- 1. Large Solids and Debris

Items such as plastics, cloth rags, sticks, wrappers, and food waste are commonly found in municipal wastewater. These are typically removed during the screening process to prevent clogging and mechanical damage.

- 2. Grit and Inorganic Sediments

Sand, gravel, and other heavy mineral particles can enter through stormwater runoff or household drainage. These are abrasive and can wear down pumps, valves, and pipes if not removed in grit chambers.

- 3. Fats, Oils, and Grease (FOGs)

FOGs are particularly prevalent in wastewater from kitchens, restaurants, and food processing units. They can coat surfaces, block flow channels, and disrupt oxygen transfer in biological treatment tanks.

- 4. Floating Scum and Light Suspended Solids

Materials such as foam, paper bits, and light organic matter tend to float and are skimmed off during preliminary separation stages.

- 5. Extreme pH Levels and Toxic Substances

Industrial effluents may introduce highly acidic, alkaline, or chemically toxic substances that can harm biological treatment units. Pre-treatment may include pH neutralization and dilution to bring these values within acceptable limits.

By eliminating or reducing these contaminants early, pre-treatment ensures that downstream biological and chemical treatment processes can operate efficiently and safely, ultimately leading to better quality effluent and reduced environmental impact.

Pre-treatment may seem like a preliminary step, but it is the foundation upon which the entire wastewater treatment process is built. By effectively removing physical debris, neutralizing harmful substances, and stabilizing flow conditions, pre-treatment safeguards equipment, optimizes treatment efficiency, and helps meet stringent discharge norms.

Frequently Asked Questions(FAQs)

Q.1 In which industries are pre-treatment solutions commonly applied?

A. Pre-treatment solutions are commonly applied in industries such as textiles, pharmaceuticals, food and beverage, chemicals, and wastewater treatment to prepare materials or effluents for further processing.

Q.2 What are the main sources of chemical pollution?

A. Common sources of chemical pollution include industrial waste, agricultural pesticides, household cleaners, mining activities, and improper disposal of chemicals.

Q.3 How does a floating oil skimmer function?

A. A floating oil skimmer works by staying on the water surface and using belts, drums, or suction mechanisms to separate and collect oil from the water.