From Risk to Response: Managing Chemical Spills

Chemical spills, though often accidental, can have devastating consequences. From industrial plants to storage depots, even a minor leak can lead to environmental contamination, workplace hazards, and costly downtime. The causes are varied, ranging from equipment failure and poor maintenance to human error and improper handling. In some cases, outdated infrastructure or a lack of emergency preparedness turns a manageable leak into a full-scale crisis.

As industries become more complex and chemical use more widespread, understanding why these spills occur and how they can be prevented is not just a matter of compliance—it’s a fundamental part of building safe, responsible, and sustainable operations. Prevention begins with awareness. This article explores the environmental consequences of spills, the regulatory framework that governs prevention, and the most effective containment methods in industrial settings.

Environmental Consequences of Chemical Spills

Frequent or poorly managed chemical spills can cause long-lasting environmental damage. The extent of harm depends on the chemical type, volume released, and how swiftly the response is executed.

- 1. Soil Contamination: Chemicals that seep into the ground can render soil infertile, harm microbial ecosystems, and pose serious risks for future use; whether for agriculture or construction.

- 2. Water Pollution: Leaks often reach nearby water bodies or seep into groundwater, endangering aquatic life, contaminating drinking water, and disrupting ecosystems. Substances like acids, heavy metals, and hydrocarbons can persist for years.

- 3. Airborne Hazards: Volatile chemicals may evaporate, releasing toxic vapours. This poses immediate health risks and contributes to broader problems like acid rain or atmospheric toxicity.

- 4. Wildlife and Ecosystem Damage: Spills that reach natural habitats can be catastrophic, killing fish, poisoning birds, and leading to long-term loss of biodiversity.

- 5. Public Health Risks: Chemical residues can enter the food chain and air supply, causing chronic health issues such as respiratory conditions, neurological disorders, and reproductive harm.

Regulations Governing Chemical Spill Prevention

To address these risks, both Indian and global regulatory bodies have put frameworks in place to promote responsible handling of hazardous materials.

- 1. Factories Act, 1948 (India): Requires facilities to follow safety measures for hazardous processes—covering storage, training, and emergency preparedness.

- 2. Manufacture, Storage and Import of Hazardous Chemicals Rules (MSIHC Rules), 1989: These rules, under the Environment Protection Act, mandate risk assessments, safety audits, and onsite emergency plans for handling dangerous chemicals.

- 3. Hazardous Waste Rules: Governs safe disposal and management of chemical by-products to protect public and environmental health.

- 4. OSHA Standards (USA): For global operations, OSHA outlines protocols for labelling, containment, PPE usage, and emergency response.

- 5. REACH and GHS (Global): These systems set global standards for chemical classification, labelling, and safety communication, enabling better hazard awareness and compliance.

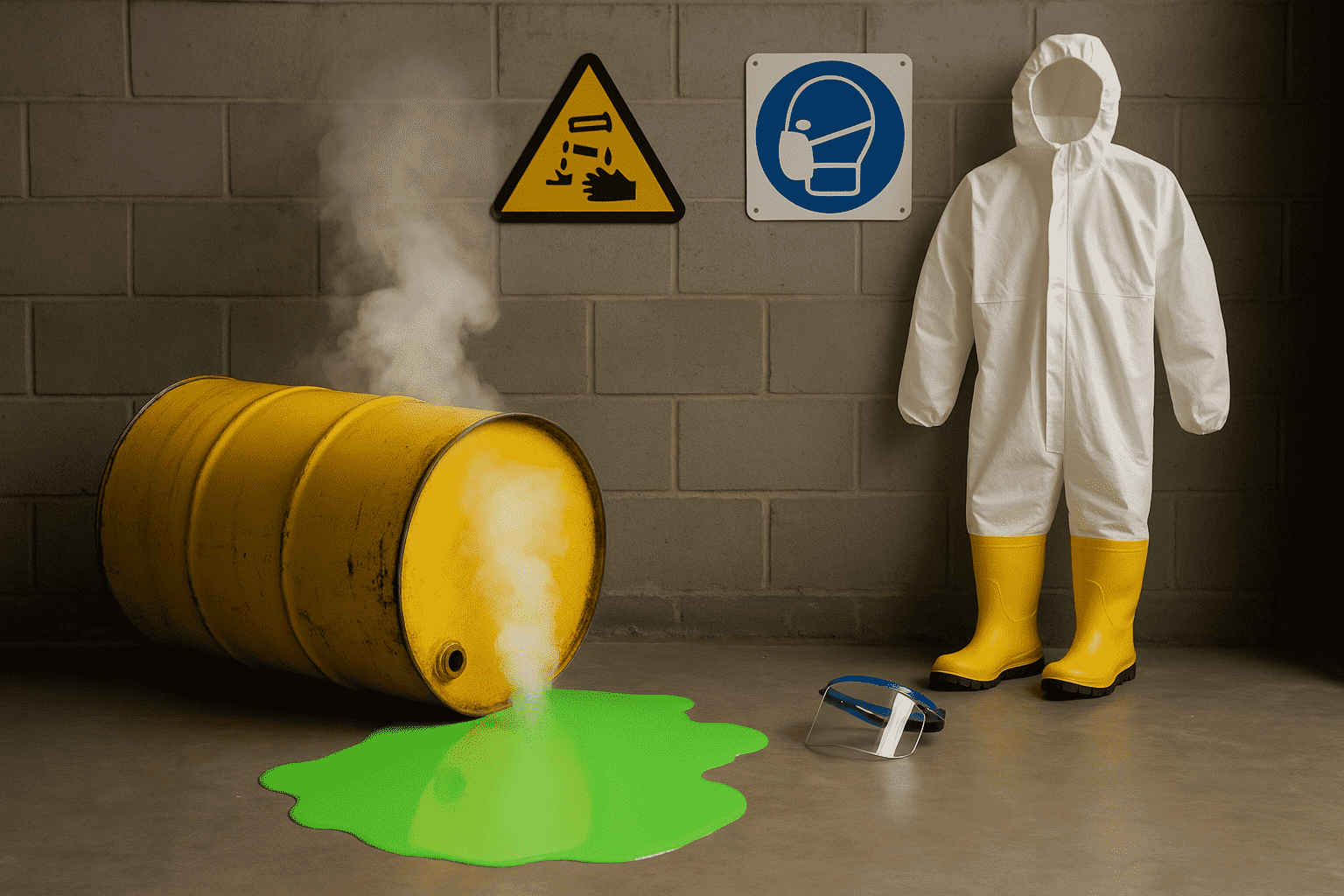

Effective Spill Containment in Industrial Settings

While prevention is ideal, containment is essential when incidents occur. Below are the most effective methods used across industries:

- 1. Secondary Containment Systems

Bund walls, trays, and pallets capture leaks at the source, preventing chemicals from reaching drains or the environment. - 2. Spill Kits and Absorbents

Equipped with pads, booms, and neutralizers, these kits enable rapid response and minimize spread in early-stage spills. - 3. Double-Walled Tanks and Piping

Provide a backup barrier to contain leaks internally—especially important for storing high-risk chemicals. - 4. Leak Detection Systems

Advanced sensors monitor pressure or flow and alert operators to potential leaks before they escalate. - 5. Drainage and Sump Systems

Designed to collect and isolate spills, these systems support safe chemical recovery and disposal. - 6. Training and Emergency Preparedness

Tools are only as good as the people using them. Regular drills, proper signage, and well-documented protocols are critical.

Chemical spills are more than operational setbacks—they are threats to people, the planet, and a company’s credibility. Fortunately, with a mix of robust regulations, effective containment systems, and a safety-first mindset, industries can significantly reduce the risk. Proactive prevention is not only about avoiding fines, but also about protecting lives and securing a sustainable future.

Frequently Asked Questions(FAQs)

Q.1 How does chemical pollution affect human health?

A. Chemical pollution can cause serious health problems such as respiratory issues, skin irritation, hormonal imbalances, cancer, and neurological disorders.

Q.2 Why is it important to respond quickly to an oil spill?

A. A quick oil spill response is crucial because oil spreads rapidly, causing significant harm to marine life, coastal ecosystems, and local economies if not contained and cleaned up promptly.