Update Chrome Browser

How does a Fixed Oil Skimmer Work? What are its Advantages and Applications?

Fixed disc oil skimmer is one of the popular oil skimmers across industries. The difference in specific gravity, surface tension, and affinity towards the media are the key factors contributing to its efficient oil recovery from the collection tank/pit.

Although all oil skimmers have the same basic working principle, the design of each oil skimmer makes it unique and most suitable for specific applications. To understand fixed disc oil skimmers better, we must know how fixed disc oil skimmers remove oil from water.

Working of Fixed Disc Oil Skimmer

Most oils have a lower specific gravity than water, which allows them to separate from water and float to the surface unless agitated. Also, most oils have little or no affinity for water which prevents the mixing of oil and water.

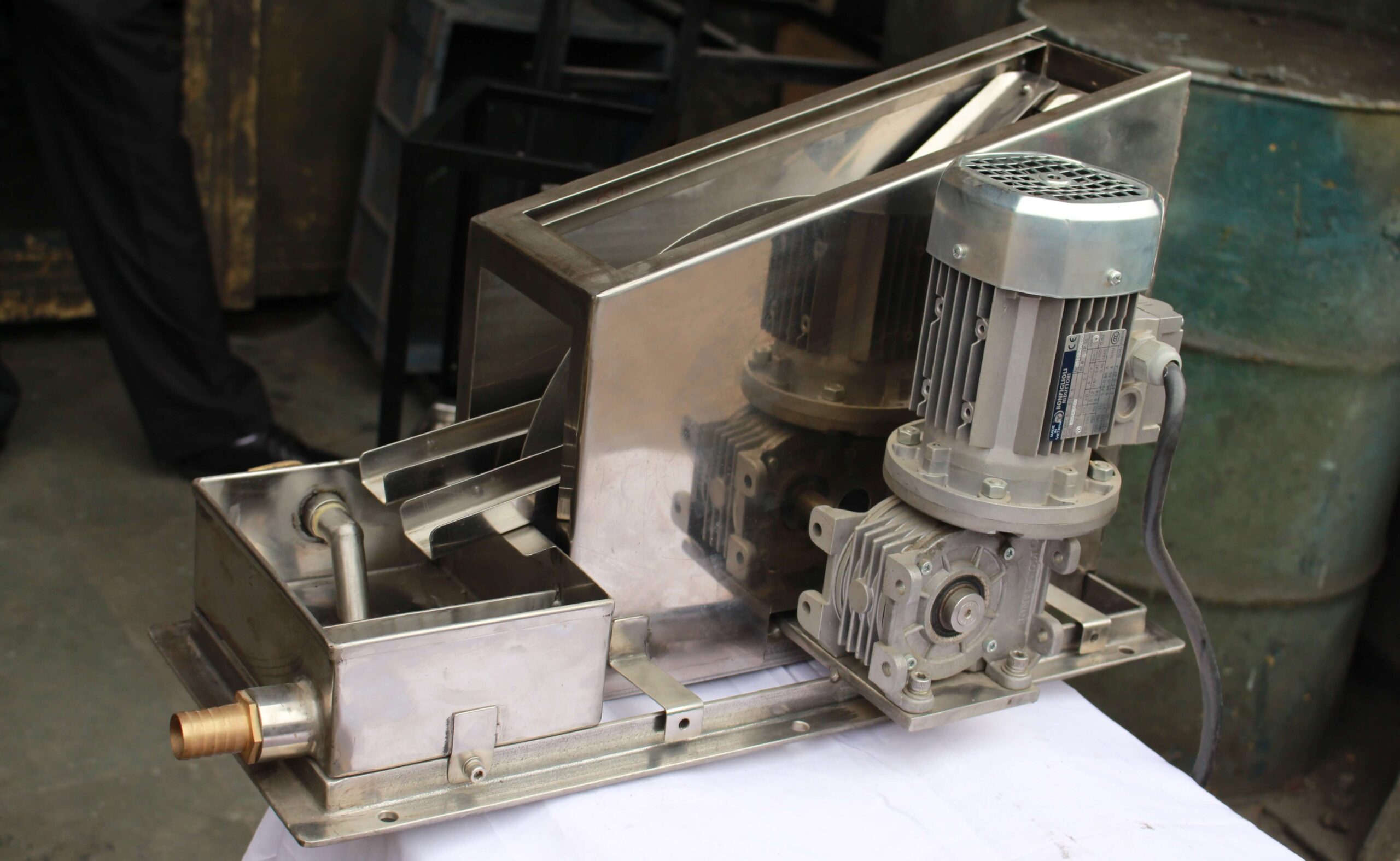

A fixed disc oil skimmer mainly consists of a disc, scrapper/wiper blades, and tray/collection tank. It is electric driven at a fixed speed.

Disc: The oleophilic circular disc material is either stainless steel or plastic. The disc is partly submerged in the medium at a fixed position. A fixed disc skimmer can make use of a single or multiple discs.

The disc rotates slowly in one direction, mitigating the possibility of emulsification. Oil skimming begins when the partially submerged disc rotates. On rotation, the floating oil adheres to the surface of the disc, is carried upward towards a pair of scrapper blades.

Wiper blades: The second stage of oil removal involves a pair of wiper blades or scrapers. Here, the disc carrying oil gets cleaned. As the disc moves upwards, towards the scrapper it passes through a pair of scrappers, which removes the oil from the surface of the disc. The clean disc, oil-free portion re-enters the medium for oil skimming.

Collection tank: The oil removed from the disc is collected in a tray or a tank for storage or transfer.

What types of contaminants can a fixed disc oil skimmer handle?

The fixed disc oil skimmer is known for its high collection efficiency. The disc can handle all floating oils from pits, sumps, and tanks.

The versatile fixed disc oil skimmer finds application across industries. Some of its applications are:

- • for removing tramp oil from the machine tool coolant tank

- • removal of floating scum and thin layers of oils

- • as a pre-treatment solution

- • at the chemical spill site

- • for oil recovery

- • as an integral part of the coolant recovery system

- • for oil, grease, and fats removal

Advantages of a Fixed Disc Oil Skimmer

- • Compact and robust design

- • Low operational and maintenance costs

- • The most inexpensive method of oil removal

- • Adaptable to varied applications and oil water separator systems

- • Skimmed oil can be recycled or reused

- • Ideal for spillage installation

- • Portable – a trolley-mounted unit can be used as mobile equipment

- • Can operate on solar power, ideal for remote locations

- • Does not use any chemicals

Fixed disc skimmer effectively treats oily water. It not only helps you recover and reuse oil/coolant but also aids compliance to the wastewater discharge norms. Adapt environment-friendly oil removal methods to improve process efficiency and safeguard the environment.

Frequently Asked Questions

Q.1 What are the advantages of using a belt oil skimmer?

A. The advantages of using a belt oil skimmer include efficient oil removal, reduced maintenance costs, and enhanced environmental compliance in industrial applications.

Q.2 What are the main components of a floating oil skimmer?

A. The main components of a floating oil skimmer typically include a floatation device, collection system, and a drive mechanism, working together to efficiently remove oil from water surfaces.