How to Fix Common Problems of Hydrocyclone Oil Separators?

Industries generate oil-contaminated water as a by-product, also oil droplets are found in wastewater. The presence of oil in wastewater makes it unfit for release into the environment. Local authorities have regulations to make sure that the wastewater meets the set parameters at discharge. Non-compliance to the regulations may lead to levy of fines and in some cases suspension of work. Oil can be separated from oil contaminated water using one of the many methods, one of which is Hydrocyclone oil separation.

Hydrocyclone Oil Separator?

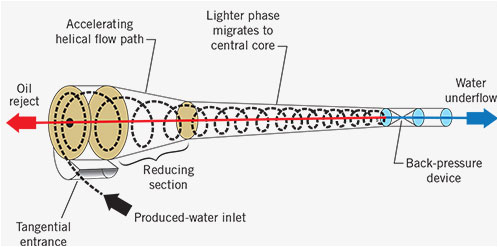

Hydrocyclone is one of the simplest and efficient oil water separators with no moving parts. It works on the principle of gravity to remove oil droplets from water/wastewater using centrifugal force.

A Hydrocyclone has three main parts: a cylindrical feed, an overflow with vortex finder, and a conical component with an apex.

Working Principle of Hydrocyclone Oil Separator

The fluid to be treated is tangentially injected into the Hydrocyclone under pressure. The geometry of the equipment and the pressure imparts centrifugal force on the fluid. The centrifugal force pushes the heavier phase outward and downward along the conical wall. The decreasing diameter of the conical part increases speed leading to improved separation. Finally, the apex is used to discharge the concentrated solids. A fast rotating upward spiral movement of the fluid in the centre of the conically shaped housing is created by the vortex finder in the overflow part. By maintaining a balanced differential pressure across the Hydrocyclone the water phase is sent in one direction to the underflow, and the oil phase is sent in the opposite direction to the overflow. The process results in a simple and effective separation, with a 2-3 seconds retention time.

Hydrocyclone is one of the best equipment to separate oil from liquid like the oil skimmers. It is widely used in various industry applications and wastewater treatment. Having said that, you may face some issues while operating a Hydrocyclone. To get the best out of it, we have listed common problems and the measures that should resolve them.

How To Fix Issues Related To Hydrocyclone Oil Separator

Switching on/off

You may come across a situation when the hydrocyclone separator will not switch on or off. You need to:

- • Check all circuit breakers and power switches, whether they are on

- • Change switch control panel mode to manual or auto as required

- • Manually check float switch operation. Cleaning or change of switch may be required

No or Low Flow

At times there can be low or no flow of water or waste oil due to the following:

- • Pump may not be running

- • Insufficient water in the wastewater sump. Also, the level switch should be in operation

- • Blockages in the suction line and floating skimmer

- • Issues in waste oil reject

- • Clogged debris strainer

Issue in Decant Tank

Under normal working conditions water level is maintained in the tank. If there is no water or high water in the waste oil decant tank you may check the following:

- • Internal Hydrocyclone components should be inspected to identify performance problem

- • Inspection of inlet sampling point to confirm that the water flows through the sleeve

- • Waste oil reject orifice should be checked for blockages

- • Check pressure regulation valve setting at treated water outlet

- • Clean debris strainer

- • Clean the sludge in waste oil decant tank

Tripping of Pump

The three probable cause for pump tripping are:

- • Pump is not cooling down due to insufficient airflow. Move the pump to a ventilated area

- • Circuit breaker has issues

- • Motor is faulty

Water Discharge Contains Oil

To address the oil issues following points should be considered:

- • An oil spillage can overload the system

- • The waste oil decant tank may be full, do empty it

- • Use of unapproved degreaser and detergents

- • Blockage in treated water discharge can affect the performance

Oil Water Separator Emits Odour

The odour indicates that there is some issue in the working which should be checked for:

- • Whether the pump is running in automatic mode or not

- • Sludge built-up in sump

- • Stagnant water in the wastewater pit. Drain out the wastewater using clean water

- • Servicing of Hydrocyclone may be required

Debris Strainer Gauge Reading

An Hydrocyclone strainer gauge may show a reading indicating that it is out of the safe zone. Do not panic, follow the below simple steps:

- • Shut down the system as mentioned in the maintenance manual

- • Clean the debris strainer

- • Remove sludge and debris from the pit while cleaning the strainer

It is a good practice to inspect and clean Hydrocyclone fortnightly. Regular examination of strainers and system operations help keep issues at bay. Annual servicing is highly recommended to make sure that Hydrocyclone performance is as per design.

Frequently Asked Questions (FAQs)

Q1. How Hydrocyclone Oil Separators issues can be identified and diagnosed?

A. To accurately identify and diagnose issues, it is important to have a thorough understanding of the system in question and access to data that can help provide insight into the issue. Additionally, having an experienced professional with knowledge in this area can be invaluable in helping to identify and diagnose issues quickly and accurately.

Q2. How does a mechanical bar screen help in removing debris from water?

A. A Mechanical Bar Screens is an essential component in the process of removing debris from water in various water treatment facilities. It plays a crucial role in ensuring the proper functioning and efficiency of wastewater treatment plants.The main purpose of a mechanical bar screen is to prevent large solid objects such as sticks, rags, plastics, and other debris from entering further into the water treatment system.

Q3. What are sluice gates and what is their purpose?

A. Sluice Gates are hydraulic structures that are used to control the flow of water in rivers, canals, and other water bodies. They are typically made of metal or concrete and are designed to open and close, allowing water to pass through or be held back as needed.