Integrated Oil Containment and Recovery Systems: A Modern Solution for Spill Response

Integrated oil containment and recovery systems provide a comprehensive solution for managing and mitigating oil spills efficiently and effectively. By combining multiple technologies and components, the system performs three main functions: containment, recovery, and, in some cases, treatment of spilled oil. Engineered for seamless operation, these systems are designed to minimize environmental impact and accelerate cleanup efforts.

Among its many components, the recovery system is pivotal in minimizing environmental and economic damage. Below, we delve into the applications and key elements that make recovery efficient and reliable.

Applications

Integrated oil containment and recovery systems are critical tools for environmental agencies, oil companies, and spill response organizations in addressing:

- • Coastal and offshore oil spills.

- • Industrial accidents in waterways.

- • Emergency responses to transportation-related spills, such as those from ships or pipelines.

To understand how these systems deliver efficient and reliable oil recovery it is essential to explore their key components and the roles they play in oil spill response.

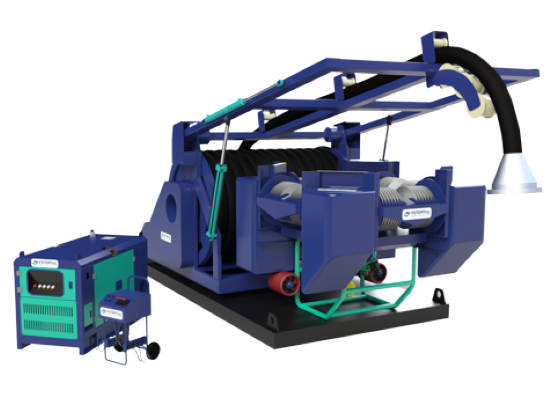

Key Components of the Recovery System

1. Heavy-Duty Skimmer with Thrusters

- • Enhanced Mobility: Thrusters enable the skimmer to navigate autonomously or be remotely controlled, ensuring precise positioning in challenging conditions like strong currents or rough seas.

- • Wide Coverage: The mobility provided by thrusters allows the skimmer to cover large areas quickly, optimizing recovery in both open waters and confined spaces.

- • Stability During Recovery: A robust propulsion system maintains stability, preventing oil from escaping the recovery zone during operation.

2. Umbilical Hose Reel Integrated with Hydraulic Cylinder Arms

- • Streamlined Operations: Hydraulic cylinder arms allow precise extension and retraction of the hose reel, simplifying the deployment and retrieval of hoses during recovery operations.

- • Durability and Efficiency: Heavy-duty umbilical hoses provide a reliable conduit for pumping oil and hydraulic power, ensuring uninterrupted recovery in demanding conditions.

- • Flexible Deployment: Integration reduces manual intervention, enhancing safety and operational speed.

3. Turntable

- • 360-Degree Maneuverability: The turntable offers rotational flexibility, enabling the skimmer to adjust its angle for optimal recovery without repositioning the entire system.

- • Efficient Operations in Confined Areas: Particularly useful in ports, harbors, or industrial sites where space is limited.

- • Reduces Downtime: Facilitates quick adjustments to changing spill dynamics, improving overall system efficiency.

4. Two Powerful Pumps

- • High-Capacity Recovery: Dual pumps significantly increase the volume of oil that can be recovered in a short time, making the system ideal for large-scale spills.

- • Redundancy and Reliability: If one pump encounters issues, the other ensures uninterrupted operation, minimizing downtime.

- • Adaptable for Oil Types: The pumps handle various oil types, including viscous oils, emulsified mixtures, and lighter fuels, ensuring flexibility and reliability across different spill scenarios.

Integrated Advantages of Oil Containment and Recovery Systems

- • Synergy of Components: Integration of these features enhances overall efficiency, enabling quick deployment, effective containment, and high-capacity recovery across diverse environments.

- • Rapid Response Capability: Thrusters, powerful pumps, and flexible deployment mechanisms ensure readiness for emergencies.

- • Versatility: Suitable for operations in open waters, coastal zones, or industrial areas, the system adapts to various spill scenarios.

- • Environmental and Economic Benefits: Faster containment and recovery reduce ecological damage and cleanup costs, contributing to environmental protection.

While recovery is a critical focus, it is important to recognize that an integrated system addresses other essential aspects of oil spill response, such as containment and storage. The different aspects of integrated systems are:

- • Containment of Spilled Oil: The use of booms and barriers helps isolate the spill, minimizing its spread and reducing potential harm to sensitive ecosystems, shorelines, and marine life

- • Temporary Storage Solutions: Recovered oil and oily water mixtures are stored in tanks or separators, preventing secondary contamination and facilitating further treatment or disposal.

The combination of high-capacity recovery, compatibility with all oil types, and easily interchangeable modules positions this skimmer as an essential tool in modern oil spill response. These features ensure adaptability, efficiency, and reliability, making it an invaluable component of any integrated oil containment and recovery system.

As oil spill response technology continues to evolve, integrated systems like this one will play an increasingly vital role in protecting our oceans and ecosystems. By combining innovative recovery methods with adaptable and efficient designs, these systems not only address today’s challenges but also pave the way for more sustainable and resilient solutions in the future. With continued advancements, these systems will not only safeguard marine life for generations to come but also set a new standard in global oil spill response.

Frequently Asked Questions (FAQs)

Q.1 How quickly can an Oil Spill Vacuum recover oil?

A. The recovery speed of an oil spill vacuum depends on the size of the spill and the type of oil. However, these vacuums are designed for rapid deployment and efficient recovery, often recovering large amounts of oil in a short period.

Q.2 How often should the Oil Spill System be maintained?

A. Regular maintenance is essential for the system’s optimal performance. The oil spill system should be inspected and serviced every few months or after each deployment.