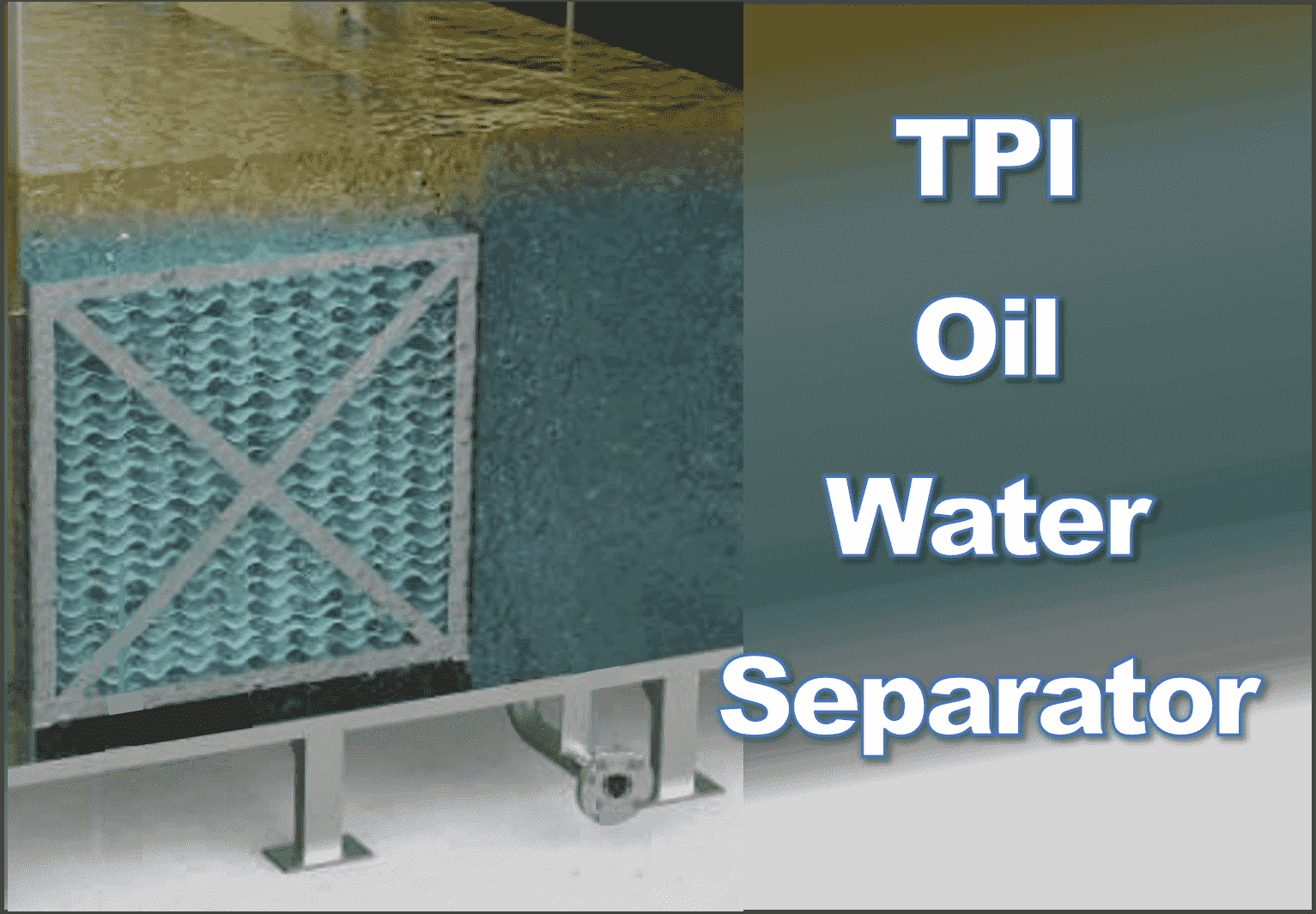

Overview of a TPI Oil Water Separator

The oil and water separation in wastewater treatment and many industrial applications is quintessential. The physical separation of oil from water can be done using a Tilted plate interceptor (TPI) oil water separator. The oil and water separation using TPI does not affect the physical or chemical properties of oil and water, giving them a second chance, reuse or recycle.

What is a Tilted Plate Interceptor Oil Water Separator?

A tpi oil water separator is a combination of gravity separation and coalescence to remove free-floating oil from water. Together, both these methods ensure efficient and speedy oil and water separation.

It incorporates several inclined parallel plates that provide a large surface area for suspended oil droplets to coalesce into larger globules. These inclined plates also aid sediments in sliding down from the top side of the plates. The inclined plate design ensures high efficiency and a small footprint.

How Does the TPI Oil Water Separator Work?

The Tilted Plate Interceptor oil water separator works on the principle of coalescence and gravity settling. The oil-water mixture flows into a tank containing inclined parallel plates. The parallel plates are inclined at an angle between 45 to 60 degrees to form a pack. The oil-water mixture is allowed to flow through the large surface area between the parallel plates. The small oil droplets coalesce to form big droplets and rise to the surface of the water. Whereas, the solids in the mixture settle on the plate surface which eventually slides down towards the bottom of the tank due to gravity. Here, the oil droplets and suspended solids adhere and coalesce, to become large and easy to separate from the water.

Once the mixture is passed through the pack, oil moves to the top surface of the water and solids settle at the bottom. The oil is skimmed using a suitable oil skimmer from the surface and clarified water is collected from the lower portion of the TPI. The water may be discharged for further treatment or environmental release. The TPI oil water separator ensures that a large amount of oil and sludge is removed before wastewater goes for further filtration processes.

The TPI oil water separator performance can be enhanced by integrating oil removal systems such as belt skimmer, slotted pipe, disc skimmer, etc. Similarly, a sand interception pit and an oil pump-out system can be incorporated.

Typical Application Areas of TPI Oil Water Separator Are:

− Refinery process water

− Effluent treatment

− Mobile oil-water separation system

− Power plant water treatment

− Coolant oil removal

− Vehicle wash water treatment

− Oil spill recovery

− Trench water treatment

− Bilge water treatment

− Hydraulic fluid tank dewatering

The compact TPI oil water separator is suitable for small and large applications, be it a vehicle wash water treatment or refinery wastewater treatment. The inclined parallel plates prove to be beneficial in speeding up the separation process and improving efficiency. The capability of the TPI oil-water separator to incorporate added features makes it suitable for a wide array of applications. The compact and modular design adds convenience of movement from one location to another.

Based on the site requirements such as hazardous/corrosive environment, an appropriate material of construction should be chosen. TPI oil water separator is available in SS, MSFRP, MSEP, etc. Industries and wastewater treatment plants can customize TPI to suit specific parameters. TPI with its high efficiency and small footprint, safeguards processes equipment, and helps abide by the discharge norms.

Frequently Asked Questions

Q.1 How do oil water separators contribute to a company’s sustainability goals?

A. Oil water separators help companies meet sustainability goals by removing contaminants from wastewater, reducing environmental impact, and ensuring cleaner discharge.

Q.2 What cost savings can you expect from implementing a tube oil skimmer?

A. A tube oil skimmer reduces costs by efficiently removing oil from water, cutting disposal and maintenance expenses, and improving system performance.