Update Chrome Browser

Overview of Floating Decanters for Wastewater Treatment Plants

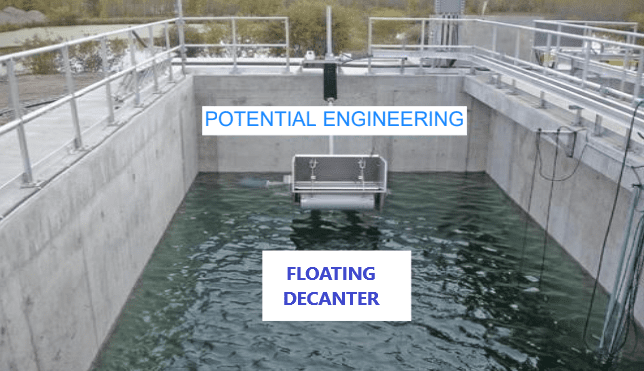

Decanters improve the process efficiency of wastewater treatment plants. They remove clarified wastewater in a sequential batch reactor (SBR). This article is an overview of floating decanters, to help you choose the right type of decanter for your wastewater treatment plant.

Function

A floating decanter is deployed in the SBR system of the wastewater treatment plant to draw treated effluent from below the surface without disturbing settled sludge. The ideal floating-type decanter must meet the following requirements:

- • Mixed liquor suspended solids (MLSS) should not enter the decanter at any time during fill, aerate, anoxic mix, or settlement phases

- • Settled sludge should not enter the decanter during the decant phase

- • Floating scum should not enter the decanter when decanting

- • The decanting rate should be controllable, if possible, to match the varying influent conditions

Types

Floating decanters can be classified into two major types motor-driven/pump decanters and floating decanters.

Floating and motor-driven decanters operate on the same working principle. They draw the treated effluent through orifices that move with the water level as it decreases in the tank. Floating decanters accomplish this passively with a floatation device, whereas in a motor-driven decanter, the arm is actively driven into the water at a controlled rate. These decanters start decanting from the surface of the water.

A floating decanter does not utilize electro-mechanical components and eliminates motors, gears, and drive units. The top and bottom levels are pre-determined and secured with stoppers to restrict the movement of the floating decanter.

Advantages of Floating Decanters Are:

- 1. Adaptable and flexible, can adjust to changing water levels

- 2. Consistent performance. Floating decanter prevents foam, scum, and floating effluent

- 3. They take maximum advantage of the distance between withdrawal points and settled solids, in varying water levels also.

- 4. Working does not disturb the settlement

- 5. Does not make use of any electro-mechanical components, resulting in low maintenance

How to Choose a Floating Decanter?

- 1. Floating decanters are designed with or without spring load valves. The advantage of a spring load valve is that it is more effective in restricting solids. Meanwhile, the floating decanters without spring load valves are ideal for use when it is ok if some solids are left in the decanted effluent, for example, supernatant from aerobic digesters is usually returned to the headworks of a treatment plant.

- 2. Floating type decanter handled varying flow rates. The flow rate is one important factor that contributes to the choice of the right floating decanter.

- 3. Certain types of floating decanters are modular in design, they can be relocated, and capacity expansion is easy.

- 4. Material of Construction is another important factor. The material should be durable, non-corrosive, and non-reactive especially if chemicals are present in the effluent.

These decanters can be operated manually or can be PLC-based. Floating decanters efficiently draw effluent, leaving a thick sludge blanket at the bottom. The type of floating decanter you choose contributes to the efficiency of the treatment plant. The right type of floating decanter will ensure optimum efficient decanting, low maintenance, and long-term smooth operations a must for industrial/municipal wastewater treatment.

Frequently Asked Questions

Q.1 How do oil containment booms help in containing oil spills?

A. Oil containment booms act as effective barriers, preventing the spread of oil spills by containing and diverting the oil, facilitating easier cleanup and minimizing environmental impact.

Q.2 How effective are floating oil skimmers in cleaning up oil spills?

A. Floating oil skimmers are highly effective in cleaning up oil spills by efficiently removing and recovering oil from water surfaces, contributing to environmental remediation efforts.