Reduce Industrial Waste with Skimming

Industrial wastes in the form of solid, liquid, or gas may threaten human health, animals, and the environment. Safe disposal of industrial wastes is, therefore, crucial to mitigate its long-lasting adverse effects.

Industrial wastes can be broadly classified into hazardous and non-hazardous. Hazardous wastes comprise heavy metals, hydrocarbons, pesticides, chemicals, etc. There are many options for treating industrial wastes, making them fit for disposal. However, the ideal approach to industrial waste management should consider the reduction and reuse of waste.

Hydrocarbons, in particular oil, are used in almost every industry either as raw material constituents or as lubricants. This oil finds its way into industrial wastewater streams in the form of waste oil. Thus, treating wastewater is one of the key responsibilities of industries to alleviate the harmful effects of oils before discharge.

Industrial wastewater makes up a large portion of the entire industrial waste. We are aware that the industrial wastewater composition contains oil of varying ratios, depending on the industrial application. Also, the discharge of wastewater containing oil must adhere to regulatory limits set by the authorities. Oils in wastewater treatment plants are generally treated by skimming methods, which can be gravity-based, suction, or adhesion. Oil skimming is a mechanical method of separating oil from water. Oil skimmers are popular in wastewater treatment plants as they are instrumental in reducing industrial wastewater. How?

How Do Oil Skimmers Help Reduce Industrial Waste?

To understand how oil skimmers are instrumental in reducing industrial waste, we must first understand the purpose and advantages of using oil skimmers, which are:

- • Oil skimmers separate oil from water without changing its properties. The outcome of oil from water separation using oil skimmers such as rotary skimmers, drum skimmers, disc skimmers, or tube skimmers gives water and oil a second chance. The precious oils drawn from the wastewater can be recycled and water can be reused. The wastewater is turned into valuable resources. Thereby considerably reducing industrial waste.

- • Oil skimmers may be used in conjunction with separator and coalescing methods. These methods are used to settle suspended solids and give buoyancy to oil droplets that are present in wastewater. The oil skimmer removes the free-floating oil from the surface of the water, the sludge is collected from the bottom of the basin, and water is drawn for further treatment. The entire process results in wastewater segregation into solid and liquid which is easy to treat thereby, contributing to effective waste treatment and subsequent waste reduction.

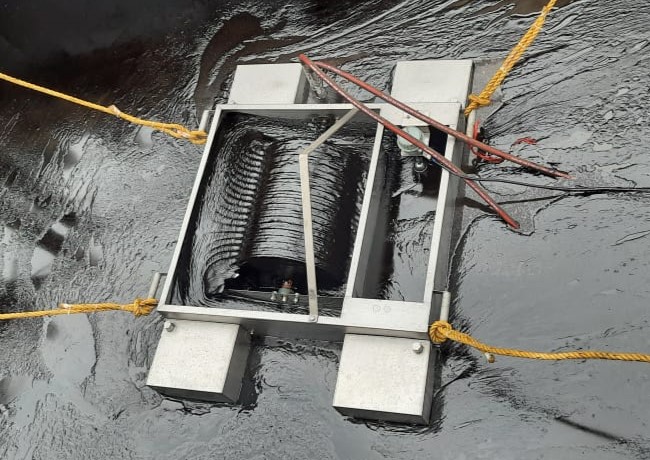

- • The industrial wastewater streams may contain oil and floating debris. Both, oil and floating contaminants (scum/foam) pose a risk to the equipment and overall process efficiency. Oil skimmers such as slotted pipes, weir oil skimmers, floating funnel, etc. are designed to address the problem of floating debris and free-floating oil. They ensure that oil and floating debris are removed from the stream, making wastewater fit for further treatment.

- • A sequencing batch reactor (SBR) is a fill-and-draw activated sludge system used in industrial wastewater treatment. The reactor aims at producing high-quality, low-volume sludge, and high-quality effluent. During the draw stage of an SBR, a fixed arm or floating weir skimmer at or just below the liquid surface draws water. The skimmer draws water without disturbing the settled solids and preventing the floating matter from being discharged. The skimmer efficiency considerably contributes to quality sludge production that can undergo further treatment. Similarly, high-quality effluent is easy to treat and recycle or reuse.

Oil skimmers differ in their function and are designed with the aim of removing oil, floating debris, and supernatant liquids. Both these functions contribute to producing high-quality effluent and sludge. In a wastewater treatment plant, sludge and water demand different treatment processes for better results. The efficiency of the treatment processes depends on the volume and quality of waste produced.

The reduction in waste volume, creation of waste recycling opportunities, and waste that is safe for disposal are the outcomes of an efficient industrial wastewater treatment plant. Industrial oil skimmers contribute towards achieving high treatment efficiency and reducing industrial waste.

Frequently Asked Questions

Q1.What types of environments are suitable for using a belt skimmer?

A. Belt skimmers are effective in various environments, including industrial sites, wastewater treatment plants, and oil spill response operations, where water surfaces require oil removal.

Q2.How long does it take to set up and start using a slotted pipe oil skimmer?

A. Setting up a slotted pipe oil skimmer typically takes 1 to 3 hours, allowing immediate operation for effective oil removal from water surfaces.