Slotted Pipe Oil Skimmers for Industrial Applications

Industries generate wastewater that generally consists of floating oil, scum, debris, etc. Removal of these contaminants with a slotted pipe is a common practice. The slotted pipe is a rotary tube with horizontal ‘C’ shaped openings that skim the contaminants. The pipe is mounted on the top of a tank to collect floating oil, scum, debris, etc.

The design of a slotted pipe is simple and effective. It typically consists of a 60° slot with reinforced gaps. When the pipe is rotated, slots facing in the direction of the flow, the floating contaminants fall into the pipe. The pipe is supported on one side by a closed flange and on the other side by an open flange. The scum, oil, and debris collected in the pipe get discharged by gravity from the open flange end. The pipe can be rotated either manually or by motorized arrangement. The slotted pipe can rotate forward and backward by manual control such as a lever or hand wheel, or by electronic control, such as an electric actuator. For applications requiring continuous operation, the slotted pipe is left in a rotated position, which otherwise is rotated at intervals.

The key points to determine the optimum performance of a slotted pipe are:

- • The slotted pipe must be installed at the right elevation

- • The diameter of the pipe must be determined based on the application

- • The slotted pipe must be flexible to skim at different levels

The common variables that affect the performance of a slotted pipe are changes in water levels, pipe diameter, slot design, and degree of rotation.

The slotted pipe is a versatile industrial oil skimmer. It stretches across the width of the process basin skimming floating oil at a large scale. The varying water levels in the basin do not affect the functioning of the slotted pipe as it can operate at different levels. It can handle oils of varying viscosity efficiently. The performance of a slotted pipe is not affected in case of a high oil flow rate, as it does not get clogged. The operation is simple and can be handled by a single operator.

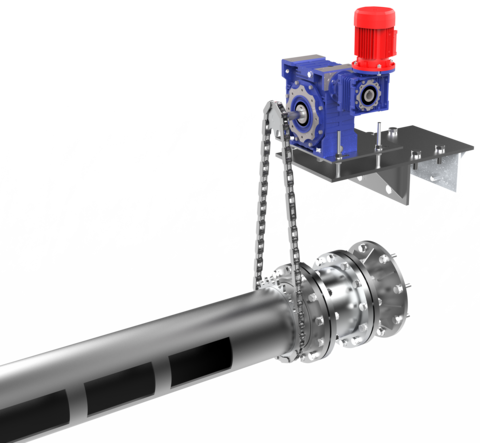

This oil skimmer has limited moving parts thus, requires low maintenance. It is easy to install and operate. The three common lifting mechanism types are manual with stick handle, manual with handwheel, and electric motor with gearbox links. The slotted pipe oil skimmer is available in MS, SS, FRP, and PVC. The choice of material of construction allows the slotted pipe to fit a wide range of industrial applications, be it corrosive or hazardous environments.

The slotted pipe system can be retrofitted easily, as a complete assembly. The assembly consists of the worm gear turning mechanism or an electric motor for rotating the pipe down to water level. The defunct rotary pipe system can be reused with the retrofit system in a matter of just a few hours of installation, time an important aspect for a manufacturing industry.

The simple slotted pipe oil skimmer efficiency can be further enhanced with an additional feature such as a heated trough. This oil skimmer has become an integral part of various industrial applications for some of the important benefits it offers over other oil skimmers, which are:

- • It can skim oil across a large surface area

- • It efficiently skims floating oil of varying viscosities

- • The efficiency of slotted pipe is better than most oil skimmers in varying water levels

- • Can operate continuously

- • It is easy to install, retrofit, operate and maintain

- • It offers high ROI

- • Requires low maintenance costs

- • Most ideal for large rectangular basins/tanks

Oil removal from wastewater is mandatory for all industries. A slotted pipe oil skimmer consumes less time, can cover a large surface area, is cost-effective, and is easy to operate and maintain. It saves money, time, and effort and skims oil efficiently. It ticks all the boxes that industries demand from an oil skimmer on a large scale. Thus, slotted pipe has proved to be important for industrial applications.

Frequently Asked Questions

Q.1 How does a drum oil skimmer compare to other oil removal methods?

A. A drum oil skimmer is more efficient than other oil removal methods because it can continuously remove large volumes of oil with minimal water content, reducing the need for further processing. Unlike chemical or dispersant methods, drum skimmers are environmentally friendly, as they do not introduce additional substances into the water, and they require less maintenance than vacuum systems.

Q.2 Why should you consider investing in an oil skimmer for your facility?

A. Investing in an oil skimmer for your facility can significantly reduce maintenance costs by efficiently removing oil from water, minimizing the risk of equipment damage and downtime. Additionally, it enhances environmental compliance by preventing oil contamination, thereby avoiding potential fines and improving sustainability efforts.