Sluice Valve Working, Applications, Installation & Maintenance

Valves play an important role in a utility system. They help control, regulate, and direct the flow of liquid. One of the valves widely used across industries is the sluice valve.

What is a Sluice Valve?

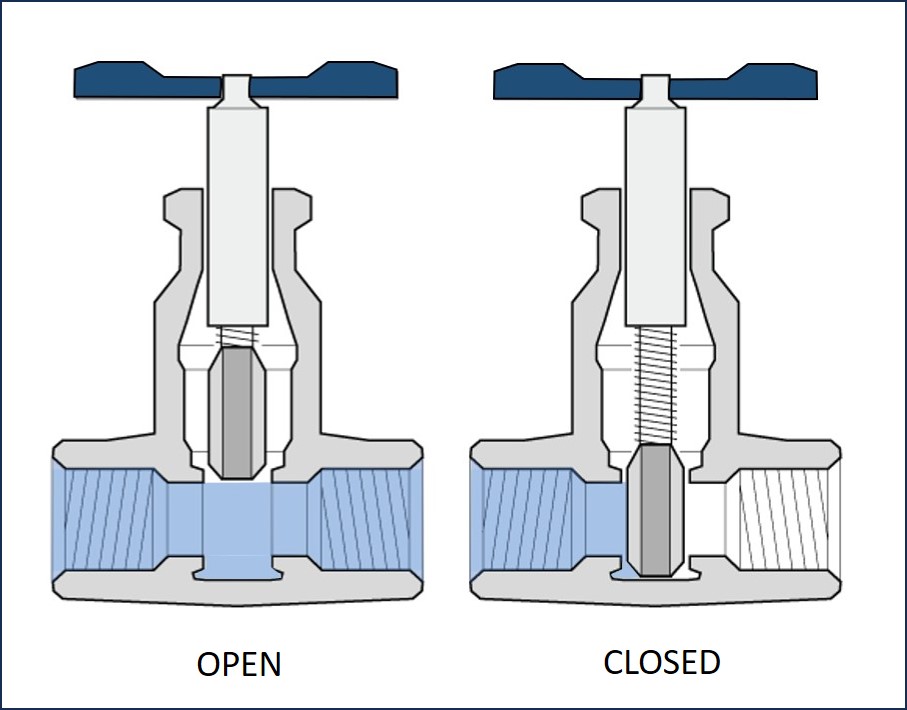

A sluice valve is a device that regulates the flow of liquid in a fully opened or fully closed position. The sluice valve is a gate or wedge-shaped disc that moves perpendicularly to the direction of the liquid entering or exiting the pipeline. The Sluice gate does not hinder the flow of the liquid in an open position. It is used along the pipe in one-directional or bi-directional flow. It is widely used in process plants to handle slurries.

How Does a Sluice Valve Work?

The Sluice valve consists of a gate, a stem, a seat, a bonnet, and an actuator to sometimes automate the flow. The gate seals the liquid flow, seats ensure sealing along with the gate, and bonnets are valve components for safe passage sealing.

- Stem: The sluice gate valve’s movement depends on a threaded stem that raises or lowers the gate or wedge-shaped disc. The gate is connected to the lower end of the stem, and the upper end has a wheel. The wheel operations can be done manually or mechanically. The wheel is required to turn several times to change positions. There are two types of wheels to raise or lower the gate in a sluice valve. The wheels are also known as spindles. Two types of spindles are:

- • Rising spindle: The stem is attached to a wedge such that the stem and wedge rise or lower together when the valve is operated. The rising spindle provides a visual indication of the valve operations.

- • Non-rising spindle: The wedge moves up or down the stem on the threads without raising or lowering the stem. The non-rising spindle may have a pointer threaded onto the upper end of the stem to indicate the valve position.

In both types, the valve opening method can be clockwise or counter-clockwise.

Where Does Sluice Valve Find Applications?

A sluice valve is ideal for use when the liquid flow must be cut off; it cannot be used as a flow regulator.

Sluice valve finds application in wastewater treatment plants and across industries in process plants to control slurries. During operations, these valves are either fully opened or fully closed. Sluice valves must not be used in partially opened positions in high flow velocity as they may cause disc and seat surface erosion. It may also cause vibration and noise.

Installation of Sluice Valve

The sluice gate valve is simple in design and operations. Proper installation and regular maintenance of sluice valves ensures long operational life and low maintenance costs.

- 1. Sluice Valve installation can be done in any direction. However, for large-size sluice valve installation, it should be in an upright position for ease of operation.

- 2. Before installation, the valve body, stem, and the gate should be examined to ensure that damages have not occurred during transit.

- 3. Pre-installation ensures the Valve is free of debris, corrosion, wrapping material, and dirt.

- 4. Ensure that the pipeline flanges are parallel and are mating the valve flange without leaving any parallel, angular, or radial gap between the flanges.

- 5. Insert and tighten the bolts with even pressure. Do not over-tighten the flange bolts or nuts because they may develop undue stress in the valve flanges and body, leading to deformation and malfunction.

- 6. Post-installation, operate the Valve to check leakages and the position of the Valve. Run check operations several times before commissioning.

The sluice valve testing should be carried out as per the guidelines/instructions provided by the manufacturer to ascertain that the Valve meets all the parameters.

Maintenance of Sluice Valve

The key parameters for checking the sluice valve are:

- • Leakage through the valve seat

- • Condition of body seat ring/wedge seat ring

- • Condition of spindle

- • Noise / Vibrations while opening or closing the Valve

Visual inspection of the seat and wedge pins is advised for the gate that is accessible. Gate operations should be observed to ensure even opening and closing of the gate against the wedge pins.

In case the sluice valve is inoperative, a once-in-month operation and maintenance exercise should be undertaken.

Before running the system, ensure that the system is pressurized-free and pressure-free. To check the sluice valve condition, remove the bonnet and the stem, followed by removal of the gate. Check the sluice gate and guide for any damage and wear. Repair or replace components if required. Lubricate stem and stem nut each time maintenance is carried out.

Refrain from over-tightening the flange bolts/nuts to make the flanges parallel forcefully. That may develop undue stresses in the valve flange body, leading to their deformation malfunctioning. The sluice valve is also known as the gate valve. It is used in pipelines requiring strict sealing that do not demand frequent switching. In some cases, liquid can flow over the top of a sluice gate in a closed position; this type of gate is known as a weir gate and shouldn’t be misunderstood as a sluice gate.

Frequently Asked Questions

Q.1 What are the key features to consider when selecting oil spill equipment?

A. When selecting oil spill equipment, key considerations include its type, capacity, adaptability to various environments, and compliance with regulations. Additionally, it’s vital to ensure quick deployment, effectiveness, and accessibility, all while integrating seamlessly with your response plan. Prioritizing these features will enhance your ability to effectively respond to oil spills while minimizing environmental damage.

Q.2 What are the benefits of using an oil-water separator machine?

A. An oil-water separator machine provides effective separation of oil and water in industrial processes, ensuring compliance with environmental regulations by preventing oil contamination in wastewater. It helps reduce environmental impact, enhances water quality, and minimizes the risk of fines or legal issues related to pollution.

Q.3 How does mechanical screen wastewater treatment work?

A. Mechanical screen wastewater treatment works by using screens with various opening sizes to remove large debris and solids from wastewater. As wastewater flows through these screens, objects like sticks, plastics, and other contaminants are trapped and separated, preventing damage to downstream treatment equipment and ensuring cleaner water for further processing.