The Three Essential Screens In Wastewater Treatment

Wastewater treatment is important for humans and the environment; similarly, screening is important for wastewater treatment.

This article will cover the purpose of screening, its types, and working to give you a detailed understanding of screening in wastewater treatment.

Screening is a unit operation to separate materials in and/or on water. It ensures that no undesired materials enter the treatment plant and mains. The unit deployed is called a screen.

The three important purposes of screens in wastewater treatment are:

1. Removal of large suspended and floating materials such as leaves, plastic, paper, etc.

2. Prevention of clogging of pumps. It guards the successive treatment from clogging and possible equipment damage caused due to clogging

3. To improve subsequent process efficiency

Wastewater composition varies and the objective of deploying a screen also varies. Based on the objective screens are used to separate materials of different sizes hence, their specifications differ. Screens types are classified based on:

- Opening size – whether coarse, medium, or fine

- Configuration – bar screen or mesh screen

- Method of cleaning the entrapped materials

- Fixed or moving screen surface

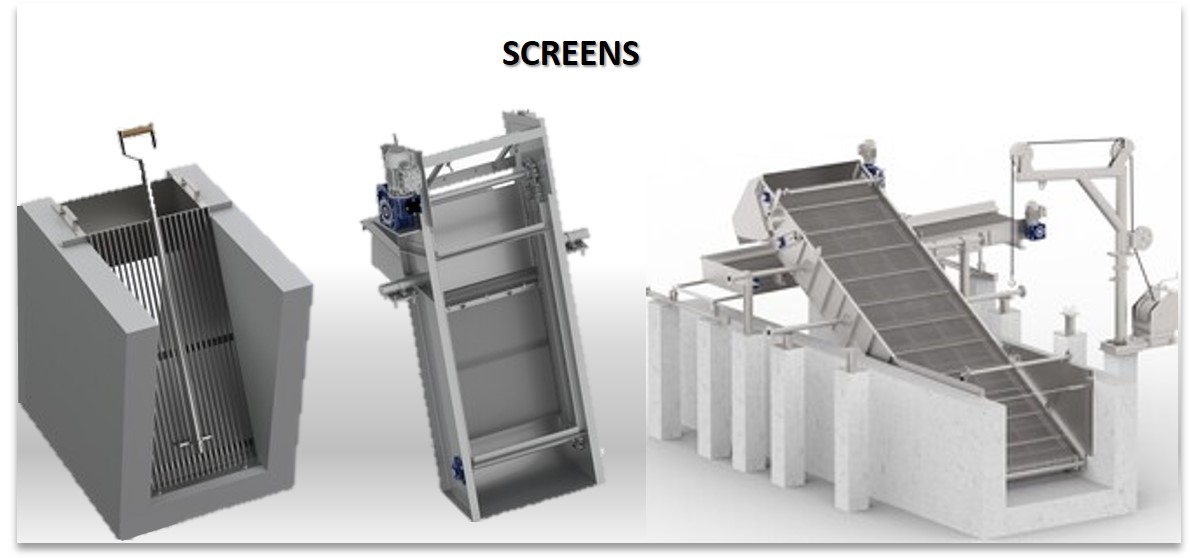

Coarse Screening in a Wastewater Treatment Plant

Coarse screening ensures that pumps, valves, pipelines, impellers, and other related equipment are protected from clogging. It is installed at the intake of wastewater before pumping, primary settling, or grit chamber. It consists of parallel bars, rods or wires, wire mesh, or perforated plates with openings generally of circular or rectangular shapes.

- It is often referred to as Racks or Bar screens

- Opening ranges 6 to 150 mm

- Removes coarse debris such as twigs, branches, rags, etc.

- Cleaning can either be manual or mechanical

Manual-cleaned Coarse Screens

Manual-cleaned coarse screens are deployed in small wastewater pumping stations. They are a good substitute as standby screens in bypass channels for service during high flow or maintenance of mechanical screens or power failure.

Mechanically cleaned Coarse Screen

Mechanically-cleaned coarse screens improve process productivity and efficiency while mitigating operational and maintenance concerns. Mechanical-cleaned bar screens are further classified into four types:

1. The chain-driven screen uses an automatic chain to clean the screen. It can go front and back while raking upstream and downstream.

2. Reciprocating rakes, also referred to as climber screens make use of a singular rake instead of numerous rakes, reducing efficiency during heavy flow.

3. Catenary bar screen is a front-cleaned, front-return Mechanical Bar Screen. The design ensures that the rakes pass over heavy objects jammed in between the bars thereby, avoiding further jamming.

4. Continuous belt screen consists of multiple rakes attached to a continuous slow rotating belt. The rakes discharge at the upper deflection point and the belt is cleaned using cleaning water jets ensuring that the screen returning into the liquid is clean. These screens effectively remove coarse and fine solids.

Fine Screening in a Wastewater Treatment Plant

Wastewater treatment makes use of fine screens that have clear openings of less than 6 mm. They are available in different forms such as perforated plates screens, mesh screens, band screens, drum screens, etc. They are made of wire cloth, wedge wire, or perforated plates. They need continuous cleaning to prevent clogging. Based on their movement they are further classified as:

- Static wedge wire screen has a clear opening range of 0.2 to 1.2 mm. It is used in large treatment plants. It demands ample floor space and daily cleaning

- Rotary drum screen is mounted on a rotating cylinder in the flow channel.

- Step type screen consists of two step-shaped thin vertical plates, one fixed and the other movable. Both the plates move across the width of the channel to form a single-screen face.

Micro Screening in a Wastewater Treatment Plant

Micro screens have an opening range of 10 to 35µm. These screens are fitted on the periphery of a rotating drum. The influent enters the drum lined with a micro screen where the solid waste is collected through backwashing and transported for disposal.

Screens are essential in wastewater treatment. They not only prevent possible equipment damage but also improve overall process efficiency. A well-designed wastewater treatment plant incorporates the right type of screens based on various parameters while contributing towards conserving our environment.

Frequently Asked Questions

Q.1 Why are oil water separators important in industrial settings?

A. Oil Water Separators are vital components in industrial settings due to their pivotal role in preventing the contamination of water bodies and complying with environmental regulations. These separators efficiently remove oil, grease, and other hydrocarbons from wastewater, ensuring that discharged water meets regulatory standards.

Q.2 Why are sluice gates important in managing water flow?

A. Sluice gates are vital for effective water flow management. By controlling the opening and closing of these gates, the flow of water in canals, rivers, and dams can be regulated. This control helps prevent flooding during heavy rains, allows for controlled irrigation, manages water levels for navigation, and aids in maintaining water quality.

Q.3 What are the key features to consider when choosing oil spill response equipment?

A. When selecting Oil Spill Response Equipment, several key features need careful consideration. These include the equipment’s efficiency in containing and recovering spilled oil, adaptability to various spill sizes, ease of deployment, and its compatibility with the type of oil in question. Durability, maneuverability, and the equipment’s response time are vital aspects, as well as its compliance with environmental regulations and industry standards.