7 Types of Oil Skimmers and Its Advantages

Grease and oil that float on liquids are removed using oil skimmers. It is an easy-to-use oil cleanup method that is both trustworthy and effective. Oil skimmers find applications in various industries such as food & beverage, steel, biodiesel, wastewater treatment, marine, chemicals, etc.

Why Do Industries Need Oil Skimmers

In manufacturing and processing plants, oil in water reduces plant efficiency. At the same time, it is mandatory to remove oil from wastewater before it is discharged into the environment. Whereas accidental oil spills require cleanup, i.e., oil removal. Hence, almost all industries require an oil skimmer suitable for their specific application.

How Do Oil Skimmers Work

Oil skimmers operate on a straightforward theory that hinges on the specific gravity, surface tension, and affinity of oils. Because most oils have a specific gravity lower than water, they typically float on the surface and may be easily separated with an oil skimmer.

Types of Oil Skimmers

Oil skimmers are either oleophilic, which relies on oil adhesion to a moving surface, or non-oleophilic.

Oleophilic skimmers incorporate specific materials to recover oil with a greater affinity for oil than water. They can be further divided into disc skimmers, drum skimmers, belt skimmers, tube skimmers, and brush skimmers. Whereas non-oleophilic skimmers comprise suction skimmers and weir skimmers.

1. Disc Skimmers

Disc skimmers are ideal for the removal of medium viscosity oils. The volume and weight of the disc skimmers are pretty large due to the size and number of rotating discs. Disc skimmers can be used for open-sea oil skimming operations. Whereas single disc skimmers are ideal for smaller skimming operations.

2. Drum Skimmers

Drum skimmers are frequently thought of for usage in hazardous conditions and locations since they can be powered by air or hydraulics. Drum skimmers are adaptable skimmers capable of handling various oils, from light oils like diesel to heavier oils like crude oil.

3. Belt Skimmers

Belt skimmers have an excellent recovery rate and great recovery efficiency. It operates on the premise that water and oil have different surface tensions. The oily effluent is passed via an unending oleophilic belt that rotates, breaking the surface tension of the water to draw and gather the floating oil. The oil is removed from the belt’s two sides by running through a set of wiper blades.

4. Tube Skimmers

Tube skimmers use tubes floating on the water’s surface to retrieve the oil. The oil is recovered by the closed-loop tube, which is scrapped, discharging the oil into a collection tank either on or shore. Tube skimmers are ideal for shallow water conditions, as the tube requires minimal water to float.

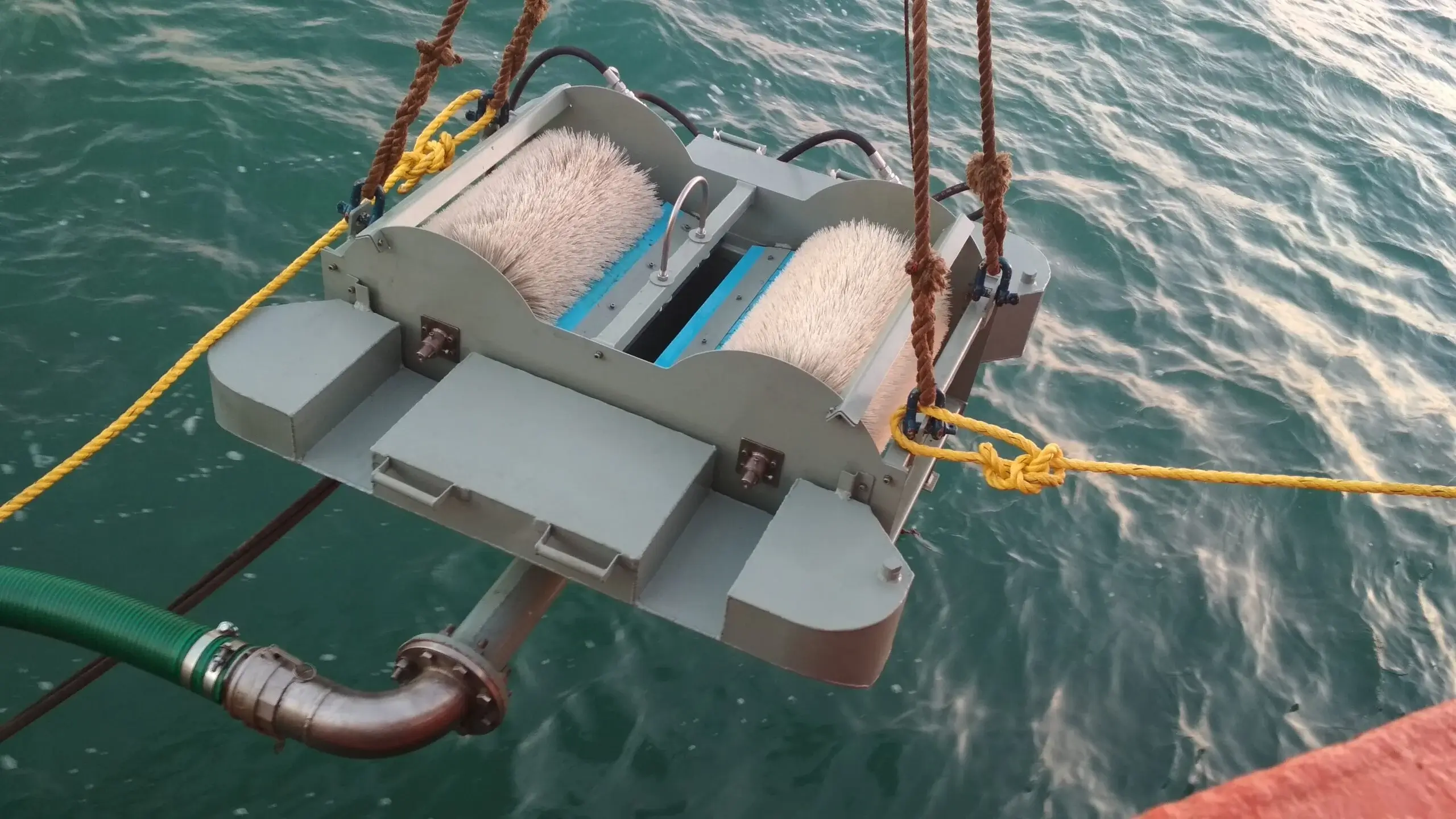

5. Brush Skimmers

Both light and heavy viscous oils can be removed with a brush oil skimmer. Brushing skimmers can be packaged in many ways, from standalone machines to modules mounted on a barge or a specially designed recovery vessel.

6. Suction Skimmers

Suction skimmers such as Floating Suction recover oil by air suction systems directly from the water surface. The skimmer uses an industrial vacuum system or a positive displacement pump. The skimmer self-repositions according to the liquid level.

7. Weir Skimmers

Light and medium viscous oils are recovered from marine oil spills using a weir skimmer. Weir skimmers are skimming apparatuses that use gravity to remove oil from the water’s surface. Weir skimmers are floating units that allow oil to flow over the weir edge and into a collecting sump by positioning the edge below the slick upper surface or at the point where floating oil meets water. The storage tanks are then pumped with the oil.

Four Key Advantages of Deploying an Oil Skimmer

Oil Skimmers are reliable equipment for oil removal; at the same time, they offer the following benefits:

1. Reduced operational cost:

Oil skimmers remove oil from water which subsequently;

− Reduce overall water consumption by extending the life of process

− Reduce maintenance of water, coolant, and filtration equipment

− Reduce the number of chemicals required to treat process water/wastewater

− Reduce costs associated with wastewater disposal

2. Improves overall plant operations:

In conjunction with the above benefit, oil removal ensures that the filtration/wastewater treatment plant works optimally. The presence of oil in water/wastewater primarily affects plant performance, which is taken care of by the use of an oil skimmer.

3. Revenue generation:

Oil Skimmers recover oil, which is valuable. Often the recovered oil can be cleaned and brought back to its original specification at a minimum cost. This oil can be recycled into other products; for example, the food industry often uses recovered waste oil for manufacturing soap, biodiesel, etc.

4. Environment-friendly:

Oil Skimmers are environment-friendly as they do not require the use of chemicals. They also address oil-related contamination concerns. And increases the potential to reuse/recycle water and valuable products.

Oil skimmers are deployed in almost every industry. Considering the application, the right type and configuration of the skimmer are essential to reap maximum benefits. Choose the best oil skimmer for your specific application with the help of an expert.

Frequently Asked Questions (FAQs)

Q1.What is a floating oil skimmer and how does it work?

A. A floating oil skimmer is a device that removes oil from water’s surface. It uses a floating mechanism with an oil-attracting material to collect the oil, which is then scraped or squeezed into a container, separating it from the water. It’s used for environmental cleanup and industrial purposes.Q2. What are the benefits of using a mechanical bar screen in wastewater treatment plants?

A. Using a mechanical bar screen in wastewater treatment plants offers benefits such as effective debris removal, reduced maintenance, improved water quality, compliance with regulations, equipment longevity, enhanced safety, and environmental protection.Q3. What are the benefits of using an oil water separator?

A. An oil water separator offers multiple benefits, including environmental compliance by removing oil and contaminants from wastewater, cost savings through reduced disposal expenses and potential oil recovery, improved water quality, extended equipment life by preventing damage, enhanced workplace safety, and alignment with sustainability goals by reducing pollution and conserving resources.