What is a Hydrocyclone Oil-Water Separator

Hydrocyclone is an efficient and effective oil-water separator. The operation of a hydrocyclone is less complicated compared to other separation methods. It finds applications across various industries.

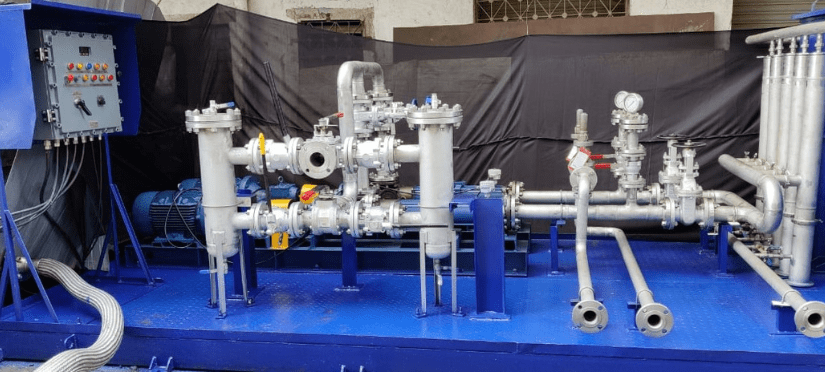

About Hydrocyclone Oil Water Separator

Hydrocyclone is a simple and efficient oil-water separator with no moving parts. It works on the principle of density difference to remove oil droplets from water/wastewater using centrifugal force.

A hydrocyclone comprises three main parts – a cylindrical feed, an overflow with a vortex finder, and a conical component with an apex.

Working Principle of a Hydrocyclone Oil Water Separator

The fluid to be treated is tangentially injected into the hydrocyclone under pressure. The geometry of the equipment and the pressure imparts a centrifugal force on the fluid. The centrifugal force pushes the heavier phase upward and downward along the conical wall. The decreasing diameter of the conical part increases the speed, leading to improved separation. Finally, the apex is used to discharge the concentrated oils. A fast rotating upward spiral movement of the fluid in the centre of the conically shaped housing is created by the vortex finder in the overflow part. By maintaining a balanced differential pressure across the hydrocyclone, the water phase moves in one direction to the underflow, and the oil phase moves in the opposite direction to the overflow. The process results in a simple and effective separation, with a 2-3 seconds retention time.

Hydrocyclone is one of the best equipment to separate oil from liquid like oil skimmers. It is widely used in various industry applications and wastewater treatment.

Industrial Applications of Hydro cyclone Oil Water Separator

1. Food Processing: Hydrocyclone is used in food processing for starch refining, to separate starch from cutting water, pulp removal, fruit juice, and oil purification, and also used to remove oil in wastewater treatment.

2. Biotechnology: Biotechnology feed streams contain small body-diameter particles, which are separated efficiently using a hydrocyclone separator.

3. Starch Manufacturing: Hydrocyclone is an alternative to centrifugal separators in the refining stage, and functions to (i) separate the starch granules from impurities (protein and sulfur) and (ii) concentrate the starch slurry.

4. Refinery & Offshore Oil: Dispersed oil in water can be separated down to ten ppm with the use of a hydrocyclone oil water separator.

5. Chemical: Hydrocyclone is used to separate solids in gas scrubbing and separating crystals in inline evaporator systems in the chemical industry.

6. Water/Wastewater Treatment: Hydrocyclone finds application as desander, de-gritting, and oil removal system.

7. Automobile: In an automotive paint system, hydrocyclone removes solids and debris from cleaning tanks.

8. Fiberglass: Hydrocyclone efficiently removes glass shot from rock wool fibers and glass fibers.

9. Coolant recovery: Various industries use hydrocyclone for coolant recovery applications.

Why Choose Hydrocyclone Systems Over Other Oil-Water Separation Methods?

Hydrocyclone systems are a preferred choice over other oil-water separation methods because of the advantages they offer, which are:

1. Efficiency: Hydrocyclone can remove oil droplets between 10-15 microns whereas traditional oil separators’ efficiency is 40-60 microns.

2. Design: There are no moving parts in a hydrocyclone. It is supplied pre-plumed and pre-wired.

3. Size: Ideal for use in small spaces. Hydrocyclone is up to 90% smaller than traditional separator systems.

4. Maintenance: The maintenance of hydrocyclone is easy and low cost as it has no moving parts.

Hydrocyclone Oil Separator is a highly effective, compact, and low-maintenance solution. This method of separation is ideal for several industrial and commercial applications.

Frequently Asked Questions

Q.1 How can a floating oil skimmer system help in environmental cleanup efforts?

A. A floating oil skimmer system aids in environmental cleanup efforts by efficiently removing oil spills from water surfaces, preventing ecological harm.

Q.2 How effective are oil containment booms in preventing oil spills from spreading?

A. Oil containment booms are designed to be highly effective in preventing oil spills from spreading by forming a barrier on the water surface, containing and restricting the movement of the oil, thereby minimizing environmental impact.