Why Mining Wastewater Treatment is Key to Sustainable Operations

Every drop of water in mining carries the weight of sustainability.

Mining is a highly water-intensive industry, with water required for mineral processing, dust control, and routine operations. Many mining sites are located in water-stressed regions, where shortages and extreme weather have created significant risks. Companies in the sector have incurred billions in losses due to water scarcity, wastewater challenges, and conflicts with local communities. Effective water management has therefore become a critical priority—not only to protect the environment but also to ensure the long-term sustainability of mining operations.

Mining Wastewater Treatment

Mining operations generate wastewater from multiple sources such as surface runoff, groundwater seepage, ore processing, and even day-to-day site use. This water often contains a complex mix of pollutants that can severely harm ecosystems and human health if not treated. Common contaminants include:

• Heavy metals – such as arsenic, lead, cadmium, mercury, copper, and zinc; toxic and bio accumulative in the food chain.

• Acid mine drainage (AMD) – acidic water enriched with dissolved metals.

• Suspended solids – silt, sand, and rock particles that increase turbidity, clog waterways, and strain wastewater treatment systems.

• Chemical reagents – cyanide, acids, and flotation agents used in mineral separation; highly toxic if released untreated.

• High salinity and sulphates – corrosive in nature, harmful to soil, water, and infrastructure.

• Oil contamination – lubricants and hydrocarbons released from mining equipment and machinery.

In fact, studies from the Offin River in Ghana’s mining regions have reported metal concentrations far above World Health Organization (WHO) standards, making the water unsafe for drinking, agriculture, or aquatic life. These risks underline why untreated mine wastewater poses a major environmental and health threat, and why effective wastewater treatment is non-negotiable for sustainable mining.

Treatment Processes in Mining Wastewater

Once we understand the pollutants present in mining wastewater, the next challenge is removing them effectively before discharge or reuse. Mining wastewater is often complex, containing heavy metals, suspended solids, oils, and chemical reagents, so treatment usually involves multiple steps working in sequence.

Here it is important to note that while the steps described in this article form a typical framework used across many mining operations, the exact design of a treatment system depends on factors such as the type of mining (coal, copper, gold, etc.), the site geology, the specific contaminants present, and the regulatory or reuse requirements. In other words, there is no ‘one-size-fits-all’ approach, each mine tailors the process to its own conditions.

- 1. pH Adjustment & Precipitation: The first step is often adjusting the pH of wastewater. When the pH is raised, dissolved metals such as iron, copper, and zinc precipitate out as insoluble hydroxides, reducing toxicity and preparing the water for downstream treatment.

- 2. Coagulation and Flocculation: After pH adjustment, a coagulant is added to destabilize fine particles. It is followed by a flocculant that binds the particles into larger clumps or flocs, making them easier to remove.

- 3. Sedimentation: Sedimentation tanks or plate clarifiers allow the heavy flocs containing silt, sand, and metal-laden solids to settle at the bottom. Sedimentation significantly lowers turbidity and prevents solids from entering rivers or groundwater. Sedimentation also reduces the load on later treatment stages.

- 4. Filtration: Water leaving the sedimentation stage is passed through filtration systems, which may use sand, activated carbon, or multimedia filters. Filtration removes fine particles and residual contaminants that are too small or too light to settle. To maintain efficiency, filters are periodically backwashed, and the wash water is recycled to earlier treatment stages.

- 5. Oil-Water Separation: Mining machinery and processing units release lubricants and hydrocarbons into wastewater. Oil-water separators that use gravity, coalescers, or skimmers remove these oils. If untreated oils form films on water surfaces, block oxygen transfer, and harm aquatic life. Importantly, effective oil removal also improves the efficiency of downstream treatments such as reverse osmosis (RO) and Zero Liquid Discharge (ZLD).

- 6. Sludge Treatment: Sedimentation and filtration generate sludge that must be carefully managed. Sludge is typically dewatered using filter presses or belt presses, reducing its volume and recovering additional water for reuse in the system. Proper sludge handling is essential to avoid secondary contamination.

- 7. Advanced and Polishing Processes: After primary and secondary treatment, advanced technologies such as membrane filtration, deionization (DI), reverse osmosis (RO), or ZLD systems are used to polish the water. These methods remove remaining dissolved salts, sulphates, and trace metals, producing high-quality water for reuse in dust suppression, cooling, irrigation, or even safe discharge.

Why Effective Mining Wastewater Treatment Matters

By effectively removing solids, oils, and other contaminants through processes like sedimentation, oil-water separation, and advanced systems like ZLD, mining companies not only protect local ecosystems but also set the stage for meeting environmental regulations and compliance standards, a critical aspect of sustainable operations.

Untreated wastewater can lead to fines, operational shutdowns, and reputational damage, while compliant water management demonstrates a company’s commitment to sustainability and community safety.

Proper treatment helps ensure that water leaving the site meets regulatory standards, reduces the risk of environmental contamination, and protects local communities that rely on nearby water sources. In addition, efficient wastewater management can improve operational efficiency by enabling water recycling and reuse, lowering freshwater demand, and reducing treatment costs in the long run.

Ultimately, complying with environmental regulations through effective wastewater treatment is not just a legal obligation—it is a crucial step toward ensuring truly sustainable mining operations.

Frequently Asked Questions (FAQs)

Q.1 What does a typical mining wastewater treatment process look like?

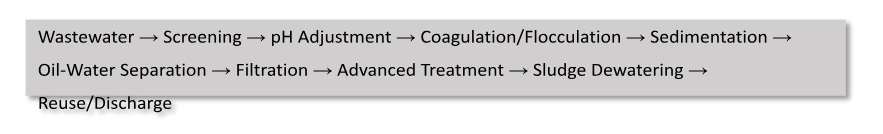

A: Mining wastewater treatment usually follows a step-by-step flow where pollutants are gradually removed until the water is safe for reuse or discharge:

Typical Flow:

- 1. Collection & Screening – Pumps and screens remove large debris, rocks, and grit.

- 2. pH Adjustment – Neutralization helps metals precipitate into insoluble forms.

- 3. Coagulation & Flocculation – Chemicals help bind fine particles into larger clumps.

- 4. Sedimentation / Clarification – Heavy solids settle at the bottom for removal.

- 5. Oil–Water Separation / DAF – Oils, grease, and floating solids are skimmed off.

- 6. Filtration – Sand filters, activated carbon, or membranes polish the water.

- 7. Advanced Treatment – Ion exchange or reverse osmosis removes dissolved salts/metals.

- 8. Sludge Dewatering – Filter presses or centrifuges remove excess water from sludge.

- 9. Reuse / Discharge – Treated water is either reused in mining operations, agriculture, or safely released.

Q2. What ancillary equipment is used in mining wastewater treatment?

A: Ancillary equipment supports the main treatment process by handling water movement, separation, and sludge management. Key examples include:

- • Pumps & Screens – move water and remove large debris.

- • Clarifiers & DAF systems – settle or float out solids, oil, and grease.

- • Filter presses & centrifuges – dewater sludge.

- • Ion exchange & membrane systems – remove dissolved metals and improve water quality.

- • Mobile plants/Power packs– provide flexible, on-site treatment.

These systems make wastewater treatment more efficient and help reduce environmental impact.

Q3. How can treated mining wastewater be reused?

A: Treated mining wastewater can be reused in multiple ways, including recycling it for mineral processing, dust control, and cooling in mining operations, using it for irrigation and agriculture, or supplying water to local industries. In some cases, advanced treatment can even make it suitable for groundwater recharge or community water use. Reusing treated wastewater reduces freshwater demand, cuts disposal risks, and helps mining operations operate more sustainably.

Q4. Is SBR wastewater treatment suitable for small communities?

A: Yes, SBR wastewater treatment is highly effective for small communities and decentralized wastewater systems because it can be scaled easily, requires less space, and handles varying loads efficiently.