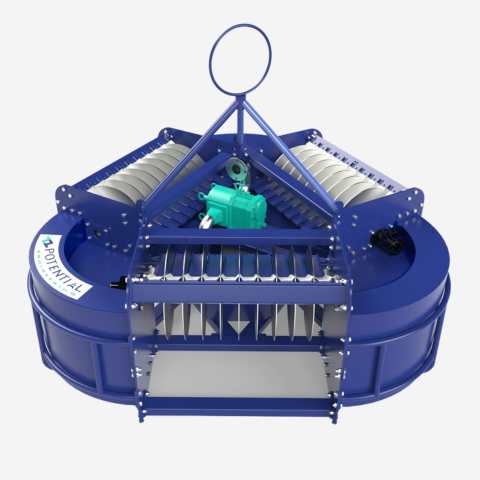

Disc Oil Skimmer Overview

Disc Oil Skimmers are robust and versatile equipment for oil recovery applications. The free-floating oil adheres to the rotating oleophilic disc, and the skimmed oil is scraped into an integrated oil collection chamber. Disc type oil skimmer are ideal for the removal of a wide range of light and medium viscous oils. They are also effective and economical. At Potential Engineering, we offer customizable solutions that integrate advanced automation and mechanisms to efficiently manage oily sludge phases. Trust us for reliable disc oil skimmer solutions designed specifically to meet your needs.

Disc Oil Skimmer Specifications

Capacity

1 to 110 m3/h

Material of Construction

SS304 / SS316/ PP/ Al

Skimmer Drive

Electric / Hydraulic / Pneumatic

No. of Recovery Modules/ Banks

Double/ Triple/ Quadruple

Oil transfer pump type

Positive displacement / AODD / Submersible Centrifugal / Gear Pump

Oil transfer pump drive

Electric/ Hydraulic/ Pneumatic/ Engine

Hydraulic power pack drive

Electric/ Diesel Engine

Control unit

Electric Control Panel/ DOL Starter/ Pneumatic Control Station

Hydraulic Hose

R2 grade; MOC: Rubber

Oil transfer hose MOC

Stainless Steel/ PVC/ Rubber

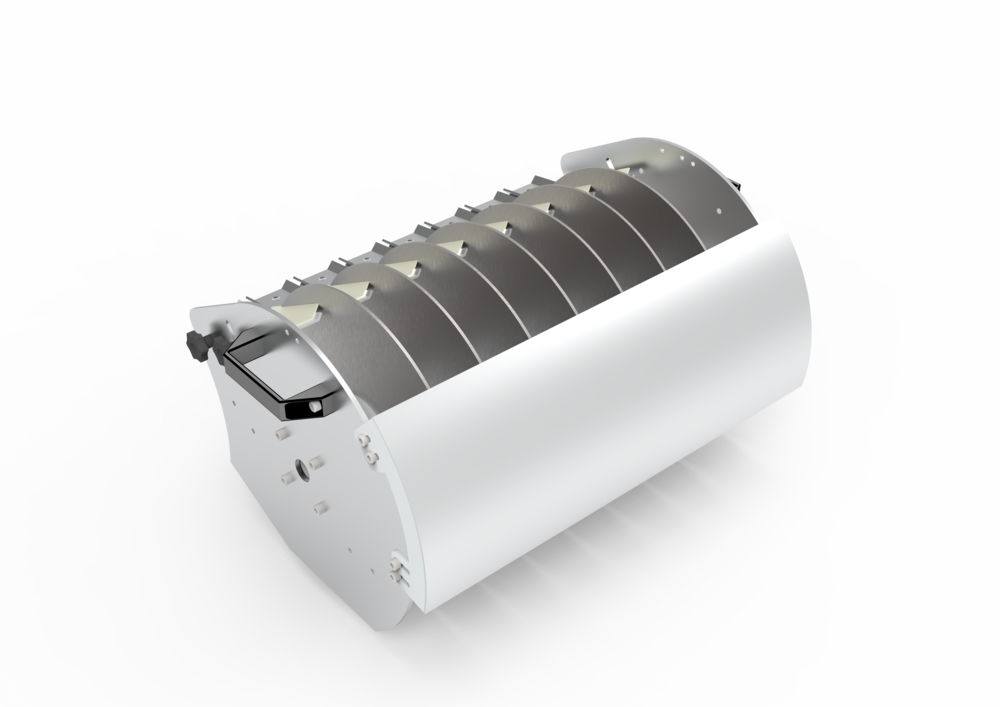

For oily sludge conditions

Sludge cutter bank with a steam nozzle

Accessories

Quick-release connectors with lock rings, Camlock Couplings, Hose Floats & Fixing ropes

Disc Oil Skimmer Features

- 1 An economical and versatile equipment

- 2 Removes a wide range of light to medium viscous oil

- 3 Easy to deploy and manoeuvre

- 4 Can be used in shallow draft

- 5 Easy to transform into a self-adjusting Weir skimmer

- 6 Interchangeable with brush and drum model

- 7 Optional automation with manual override available

- 8 Oily sludge cutter with steam arrangement, an optional feature

- 9 Low maintenance cost

- 10 All parts are easily available