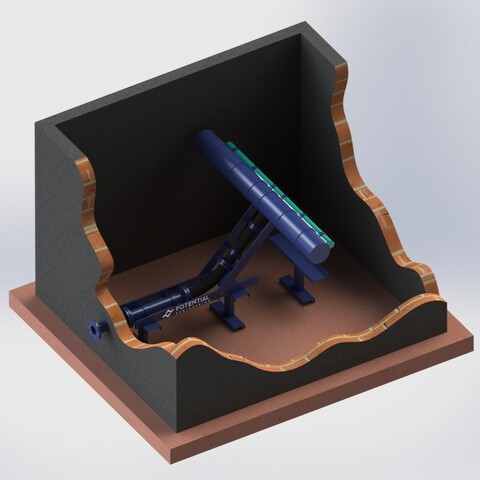

Effluent Decanter Overview

The scum/solids, excluding the type of floating decanter, use float to move up & down in the basin and employ spring-loaded non-return valves to isolate the effluent piping from the surrounding mixed liquid. The design eliminates motors, gears, drive units, and other electromechanical components. Using a stopper restricts the top and bottom movement of the decanter. It can be operated manually or PLC-based.

Effluent Decanter Specifications

Decanter Size

150 mm, 200 mm & 250 mm

Decanter Capacity at 3 m height (m3/h)

250, 425 & 680

Decanter Capacity at 1 m height (m3/h)

150, 215 & 350

Control

PLC based with manual overrides