The 5 Clear Benefits of Oil Skimming

What is Oil Skimming?

Oil skimming is a process that removes oil floating on the surface of a liquid. The device used to skim oils is known as an oil skimmer.

Oil skimming plays a crucial role in wastewater treatment. It benefits businesses and the environment by recovering oil from wastewater that can be recycled and reused.

How Do Oil Skimmers Work?

An oil skimmer is a simple device. Oil skimmers take advantage of the difference in the properties of water and oil.

Difference in specific gravity, surface tension, and affinity enables oil to adhere to the surface of the skimmer. Oil on the surface of the skimmer is removed from the surface and sent to a collection tank.

The skimmer’s surface to which oil adheres has oleophilic property . With the help of wipers, oil is scraped from the surface of the skimmer.

The Five Key Benefits of Oil Removal

- 1. Cost-Savings: The removal of oils mitigates the risk of oil clogging in machines/filters, resulting in reduced use of consumables and equipment used for cleaning.Oil skimmers safeguard delicate instruments and filters by limiting their exposure to cleaning chemicals and equipment, minimizing wear and tear, and improving lifespan. Reduced expenses on consumables & maintenance and improved lifespan of equipment result in substantial cost-savings.

- 2. Revenue generation: Oil Skimmers recover oil that may be valuable. Skimmed oils can be brought back to their original specifications by a simple cleaning process at a minimum cost. The food industry often uses recovered oil for manufacturing soap, biodiesel, etc.

- 3. Improves overall plant performance: The presence of oil in wastewater affects plant performance by reducing process efficiency. Oil skimmer efficiently removes oil from wastewater, contributing to improved plant performance.

- 4. Environment-friendly:Oil Skimmers are environment-friendly, as they do not use chemicals to remove oil. Oil-related wastewater contamination also gets eliminated with the use of an oil skimmer. Oil skimmer increases the potential to reuse/recycle water and valuable products.

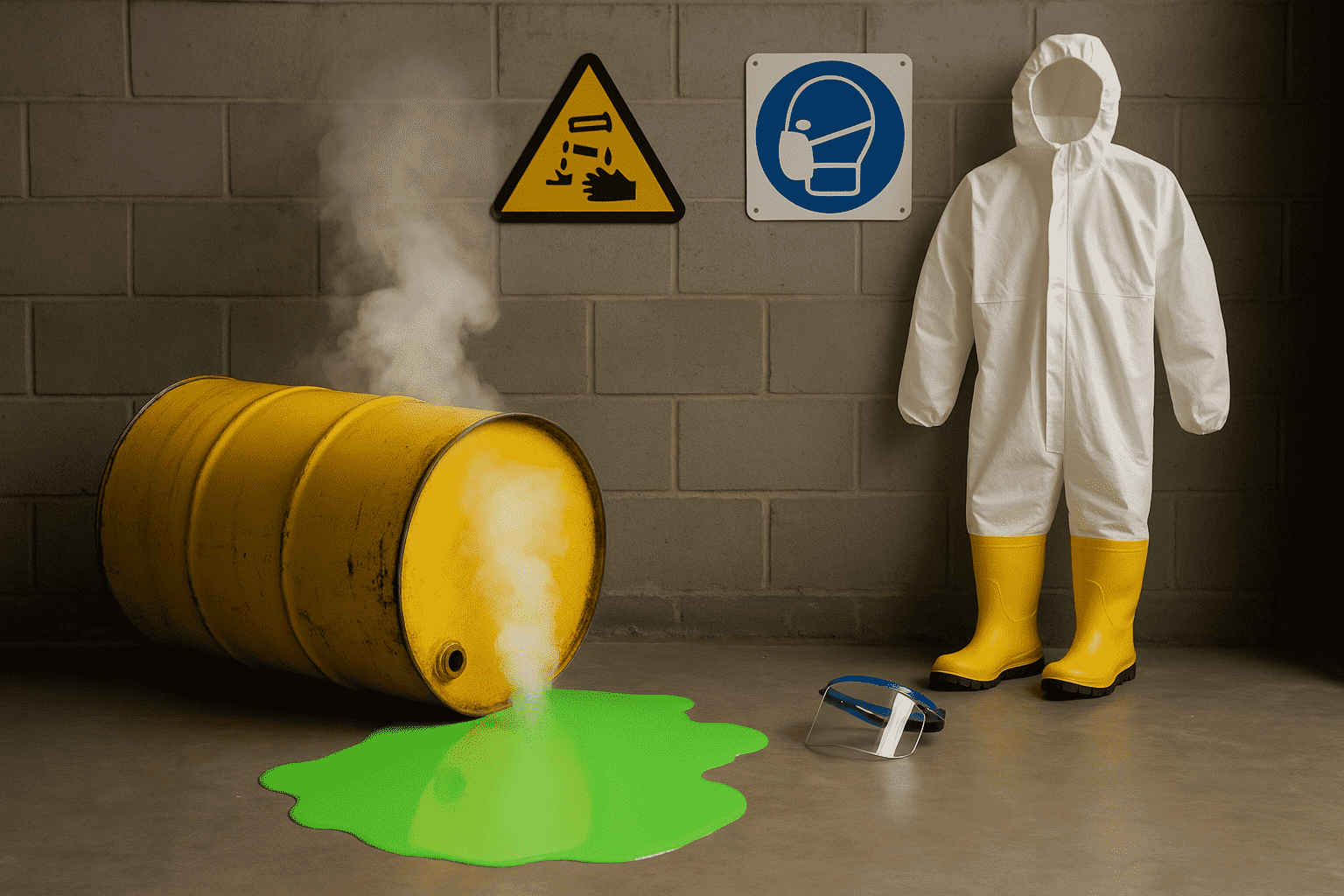

- 5. Safe Work Environment: The operation of an oil skimmer ensures the movement of the surface of wastewater, reducing the risk of bacteria growth that may lead to foul odor and skin alignment that arise due to its exposure. Oil skimmer makes the environment safe for workers on-site.

The right type of oil skimmer for a specific application and site conditions reaps maximum benefits. Depending on the coverage area, flow, and oil viscosity, the selection of the type of oil skimmer may vary.

Oil skimmers are available in different types viz., belt skimmers, tube-type skimmers, drum skimmers, disk skimmers, suction skimmers, and weir skimmers. These skimmers are cost-effective, easy to operate, and highly efficient equipment. They find application as oil spill equipment, and in industrial & wastewater treatment processes.

Oil skimmers are instrumental in safeguarding our environment, improving process efficiency, and reducing operational costs. They provide a green solution that is essential in every wastewater treatment plant and as an emergency oil spill response.

Frequently Asked Question

Q.1 What are some industries or applications that commonly use industrial oil skimmers?

A. Industrial oil skimmers are commonly used in industries such as manufacturing, wastewater treatment, mining, and food processing to remove oil and other contaminants from water surfaces.

Q.2 How does a mechanical bar screen help in removing solid waste from water?

A. A mechanical bar screen helps remove solid waste from water by using a series of rotating or reciprocating bars to physically intercept and lift debris and solids out of the water, preventing them from passing further downstream in the wastewater treatment process.

Q.3 How can investing in an oil water separator save costs in the long run?

A. Investing in an oil water separator can save costs in the long run by preventing environmental fines and cleanup expenses associated with oil contamination, ensuring compliance with regulations, and reducing maintenance and disposal costs.